A sinking feeling in your stomach—that’s the last thing you want on the water. Protecting your vessel from flooding is paramount, and a properly functioning bilge pump system is your first line of defense. Understanding how to correctly connect a bilge pump to a float switch is crucial for ensuring its automatic operation and keeping your boat afloat.

Imagine this: you're out enjoying a beautiful day on the lake when a sudden downpour hits. Water begins to accumulate in the bilge. Without a properly wired bilge pump and float switch, you'd be frantically bailing water, potentially jeopardizing your safety and your boat. This is where the importance of a correct bilge pump float switch wiring setup shines through.

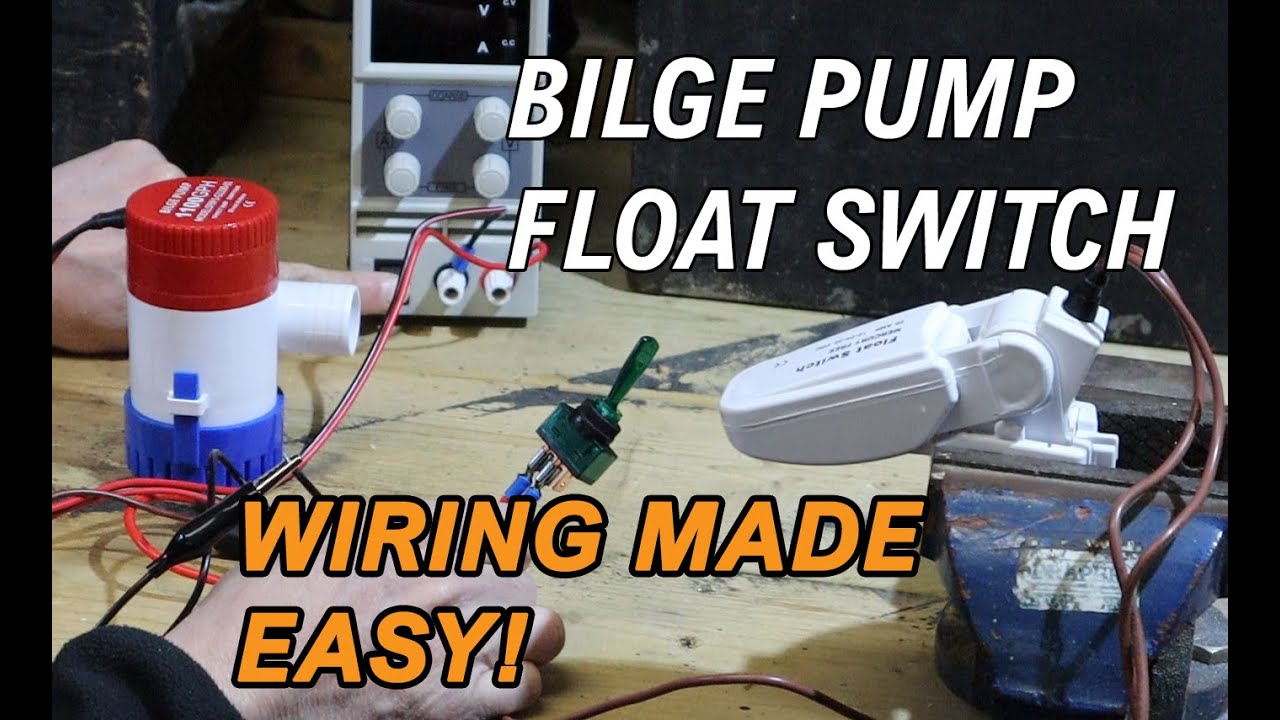

The float switch acts as the brain of the automatic bilge pumping system. This small device, often a sealed, buoyant switch, detects rising water levels. When the water reaches a certain point, the float switch activates, triggering the bilge pump to remove the unwanted water. The float switch connection ensures the pump operates only when needed, conserving battery power and extending the pump's lifespan.

The history of bilge pumps dates back centuries to manual methods of removing water from ships. However, the advent of automatic electric bilge pumps and float switches revolutionized boat safety. This automated bilge pump float switch configuration eliminates the need for constant monitoring and manual intervention, providing peace of mind and a safer boating experience.

The core of correct bilge pump float switch wiring lies in understanding the electrical circuit. This generally involves connecting the float switch in series with the positive wire leading to the bilge pump motor. The float switch essentially acts as a gatekeeper, allowing power to flow to the pump only when the float rises with the water level.

A typical bilge pump float switch wiring diagram will show the positive wire from the power source connecting to one terminal of the float switch. The other terminal of the float switch connects to the positive wire of the bilge pump. The negative wire of the bilge pump is connected directly to the negative terminal of the power source (usually the boat's battery). This configuration ensures the float switch controls the power supply to the pump.

Benefits of a properly wired bilge pump and float switch system include: automated bilge water removal, prolonged pump lifespan due to reduced run time, and increased safety by preventing potential flooding.

Action Plan for Bilge Pump Float Switch Wiring

1. Gather necessary materials: bilge pump, float switch, marine-grade wiring, wire connectors, fuse holder, fuse.

2. Disconnect the battery's negative terminal.

3. Mount the bilge pump and float switch according to manufacturer instructions.

4. Connect the wires following the wiring diagram.

5. Reconnect the battery and test the system by manually activating the float switch.Advantages and Disadvantages of Automatic Bilge Pump Systems

| Advantages | Disadvantages |

|---|---|

| Automatic operation | Requires a functioning electrical system |

| Increased safety | Can fail if not properly maintained |

| Prolonged pump lifespan | Float switch can get stuck |

Best Practices: 1. Use marine-grade wiring. 2. Install an inline fuse. 3. Test the system regularly. 4. Inspect the float switch for debris. 5. Consult your boat's manual for specific wiring instructions.

FAQ:

1. What type of wire should I use? (Marine-grade wire)

2. Where should I mount the float switch? (In a location where it will reliably detect rising water)

3. How do I test the system? (Manually lift the float switch)

4. What size fuse should I use? (Consult your bilge pump's specifications)

5. Why isn't my bilge pump working? (Check the wiring, fuse, and float switch)

6. Can I wire multiple bilge pumps to one float switch? (Yes, with the correct wiring configuration)

7. What are the common float switch problems? (Sticking due to debris, faulty wiring)

8. How often should I inspect my bilge pump system? (At least once a season)Tips and Tricks: Use waterproof connectors to prevent corrosion. Ensure the float switch has ample free movement. Consider installing a high-water alarm for added safety.

In conclusion, correctly wiring your bilge pump and float switch is essential for boat safety and peace of mind. It's a relatively simple task that can save you from costly repairs and potentially dangerous situations. Understanding the basics of the electrical circuit, following a clear wiring diagram, and adhering to best practices ensures a reliable automatic bilge pumping system. Remember, regular inspection and maintenance are crucial for keeping your bilge pump system in top working condition. Don't let a flooded bilge ruin your day on the water—invest the time to properly wire your bilge pump and float switch today. Your safety, and the longevity of your boat, depend on it. This knowledge empowers you to maintain a critical safety system, allowing you to enjoy your time on the water with confidence, knowing that your boat is protected from unexpected flooding.

Bilge Pump Float Switch Wiring Diagram - Trees By Bike

Bilge Pump Wiring Diagram With Float Switch - Trees By Bike

Wiring Rule Bilge Pump - Trees By Bike

Bilge Pump Float Switch Wiring - Trees By Bike

DIAGRAM Wiring A Bilge Pump And Float Switch Diagram - Trees By Bike

DIAGRAM Wiring A Bilge Pump And Float Switch Diagram - Trees By Bike

Bilge Pump Wiring Diagram - Trees By Bike

Bilge Pump Float Switch Wiring Diagram - Trees By Bike

How to wire a bilge pump - Trees By Bike

Float Switch Wiring Diagram - Trees By Bike

Wiring Auto Bilge Pump - Trees By Bike

Bilge Pump Float Switch Wiring - Trees By Bike

Rule Float Switch Wiring - Trees By Bike

Rule 500 Bilge Pump Wiring Diagram Rule Automatic Bilge Pump Wiring - Trees By Bike

Pump Float Switch Wiring Diagram - Trees By Bike