Ever wondered about that crucial connection between your boat's bilge pump and its power source? It's more than just a wire; it's a lifeline. Choosing the correct bilge pump wire gauge is paramount for safety and efficient operation. A wire that's too thin can overheat, potentially causing a fire hazard, while one that's too thick can be unnecessarily expensive and difficult to work with.

Selecting the right wire gauge for your boat's bilge pump might seem like a small detail, but it's actually a crucial aspect of boat maintenance. It directly impacts the pump's performance and your overall safety on the water. Getting it right ensures your bilge pump can effectively remove unwanted water, keeping your vessel afloat and preventing potential electrical issues.

The core principle behind bilge pump wiring is understanding the relationship between the pump's amperage draw and the wire's capacity to carry that current. Essentially, a higher amperage pump requires a thicker wire (lower gauge number) to handle the electrical load safely. This prevents overheating and ensures the pump receives sufficient power to operate efficiently.

Figuring out the correct bilge pump wire size involves a few key steps. First, you need to determine the amperage draw of your bilge pump, which is usually listed on the pump itself or in its manual. Next, consult a wire gauge chart (readily available online or at marine supply stores) to find the appropriate wire gauge for that amperage and the length of the wire run from your battery to the pump.

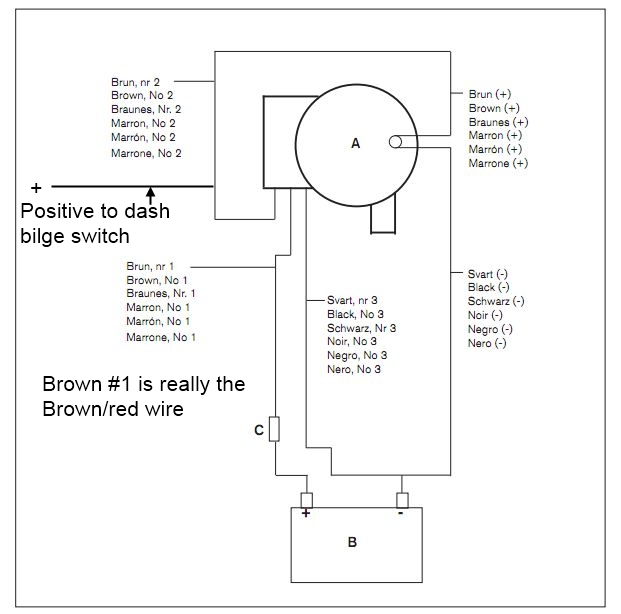

Beyond just choosing the right gauge, the overall installation process is equally important. Properly connecting the wires, using marine-grade connectors and ensuring adequate fusing are all essential for a safe and reliable bilge pump system. Neglecting these steps can lead to corrosion, electrical failures, and even potential fire hazards.

Historically, bilge pumps were manually operated, but with the advent of electric pumps, correct wiring became crucial. Early electrical systems often lacked proper grounding and fusing, leading to safety concerns. The evolution of marine wiring standards has significantly improved boat safety, emphasizing the importance of correct wire sizing and installation techniques for bilge pumps.

One common issue is using wire that's too small for the pump's amperage. This can cause the wire to overheat, melt the insulation, and potentially start a fire. Conversely, using excessively large wire can be cumbersome and expensive, adding unnecessary weight to the boat.

A simple example: A small bilge pump drawing 5 amps might require 16-gauge wire for a short run, but a larger pump drawing 15 amps would need a thicker 12-gauge wire, especially for longer runs. This demonstrates how amperage and wire length influence gauge selection.

Advantages and Disadvantages of Different Wire Gauges

| Gauge | Advantages | Disadvantages |

|---|---|---|

| 16 AWG | Suitable for low-amp pumps, easier to work with | Not suitable for high-amp pumps, longer runs can lead to voltage drop |

| 14 AWG | Good for medium-amp pumps, reasonable flexibility | Can be slightly overkill for very low-amp pumps |

| 12 AWG | Handles higher amperage, minimizes voltage drop over longer distances | Less flexible, more difficult to work with in tight spaces |

| 10 AWG | Ideal for high-amp pumps and long runs, minimal voltage drop | Expensive, very stiff, challenging to work with |

Best Practices:

1. Always consult a wire gauge chart.

2. Use marine-grade tinned copper wire.

3. Install an inline fuse near the battery.

4. Use waterproof connectors.

5. Regularly inspect wiring for damage.

Frequently Asked Questions:

1. What happens if I use the wrong gauge wire? Overheating, fire hazard, pump malfunction.

2. Where can I find a wire gauge chart? Online, marine supply stores.

3. What type of wire should I use? Marine-grade tinned copper wire.

4. Do I need a fuse? Yes, an inline fuse near the battery is essential.

5. How often should I check my bilge pump wiring? Regularly, at least annually.

6. Can I extend the wiring? Yes, but ensure the correct gauge is maintained for the extended length.

7. What are marine-grade connectors? Waterproof connectors designed for the harsh marine environment.

8. What size wire do I need for a 10 amp bilge pump? Consult a wire gauge chart, considering wire run length.

Tips and Tricks: Label wires clearly, use heat shrink tubing on connections, and secure wiring to prevent chafing.

Choosing the correct wire gauge for your boat's bilge pump is a fundamental aspect of boat safety and maintenance. A properly wired bilge pump ensures efficient water removal, protects against electrical hazards, and provides peace of mind on the water. By understanding the relationship between amperage, wire gauge, and length, boat owners can make informed decisions and install a reliable bilge pump system. Remember to always consult a wire gauge chart, utilize marine-grade materials, and adhere to best practices for a safe and effective installation. Don’t take chances with your safety – take the time to choose and install the correct wire gauge for your bilge pump. Your boat, and your peace of mind, will thank you.

How Do I Know If My Bilge Pump Is Working at Myles Fife blog - Trees By Bike

How To Install A Bilge Pump And Float Switch at Josephine Neal blog - Trees By Bike

Wiring Diagram For An Automatic Bilge Pump Wiring Bilge Pump Diagram - Trees By Bike

How To Wire A Bilge Pump Switch - Trees By Bike

Float Switch Wire Diagram - Trees By Bike

How To Wire An Automatic Bilge Pump - Trees By Bike

How To Install A Bilge Pump And Float Switch at Josephine Neal blog - Trees By Bike

Pump Float Switch Wiring Diagram - Trees By Bike

Attwood Auto Bilge Pump at Rebecca Beazley blog - Trees By Bike

How To Wire Bilge Pump - Trees By Bike

How To Wire A Bilge Pump - Trees By Bike

How To Wire A Bilge Pump Switch - Trees By Bike

How To Wire An Automatic Bilge Pump - Trees By Bike

Rule 3 Way Bilge Pump Rocker Switch Wiring A Fan - Trees By Bike

Wiring A Automatic Bilge Pump - Trees By Bike