Ever found yourself staring at a toolbox full of sockets, feeling utterly lost? You're not alone. Understanding SAE socket sizes can be a real headache, especially for those new to DIY projects or professional mechanics just starting out. But what if I told you mastering these sizes is the key to unlocking a world of successful repairs and builds? It's true. This comprehensive guide will walk you through everything you need to know about SAE (Society of Automotive Engineers) socket sizes, transforming you from a confused beginner to a confident wrench-wielder.

Let's face it: a jumbled mess of sockets is about as useful as a chocolate teapot. Imagine trying to loosen a bolt with the wrong size socket – stripped bolts, rounded corners, and a whole lot of frustration. Knowing your SAE socket sizes is like having the right key for every lock. It's the foundation of efficient, effective work, whether you're tackling a simple home repair or a complex engine rebuild. This guide will provide you with the essential knowledge to navigate the world of SAE sockets, ensuring you always have the right tool for the job.

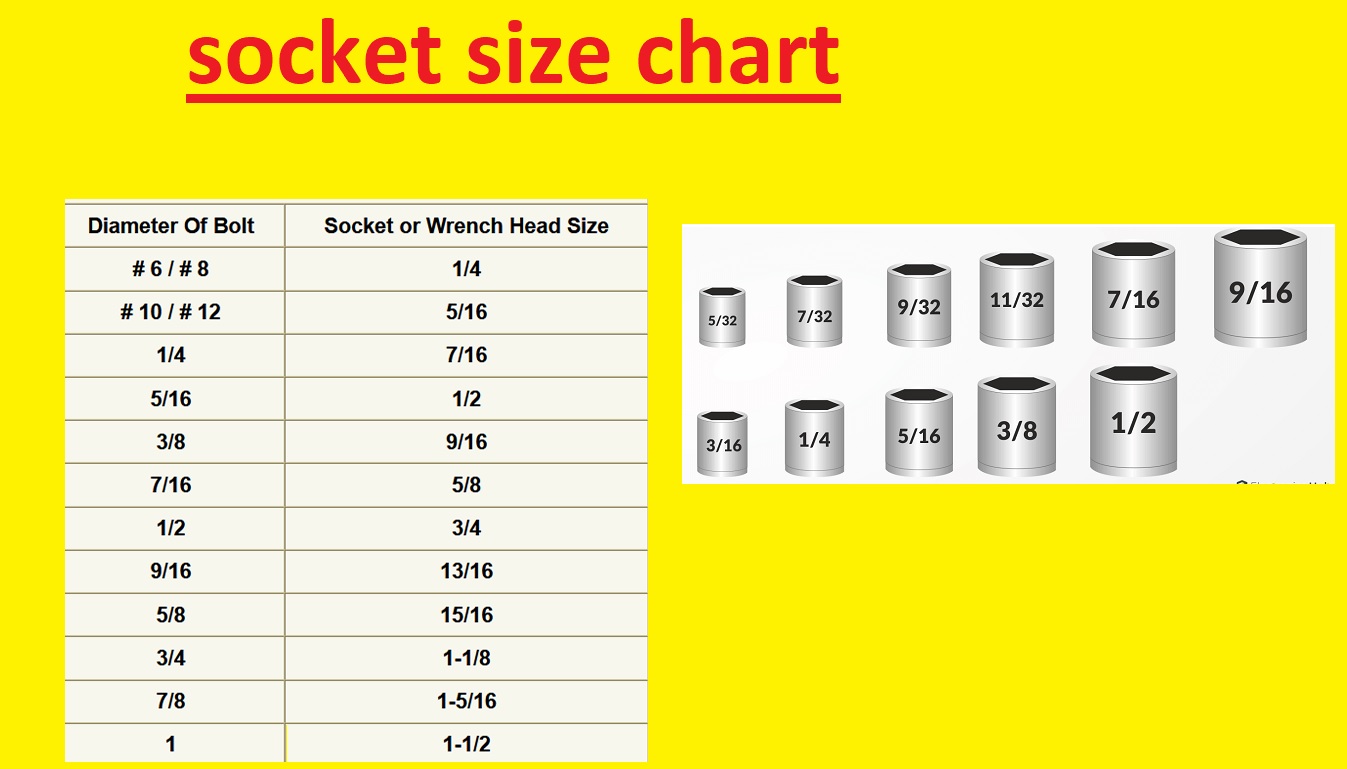

So, what exactly are SAE socket sizes? Simply put, they are a standardized system for measuring the size of sockets used with fasteners like nuts and bolts. The SAE system uses fractional inches, unlike the metric system which uses millimeters. You'll commonly see sizes like 1/4", 3/8", 1/2", and so on. Understanding these fractions and how they relate to different fasteners is crucial. This guide will equip you with a comprehensive understanding of these sizes, including an SAE socket size chart, so you can confidently select the correct tool every time.

The SAE system has a rich history, originating in the early 20th century with the Society of Automotive Engineers in the United States. This standardization was revolutionary, bringing order to the chaotic world of fasteners and tools. Before standardized socket sizes, compatibility issues were rampant, making repairs and manufacturing incredibly inefficient. The adoption of SAE standards streamlined processes and paved the way for the modern automotive and manufacturing industries.

One of the biggest challenges with SAE socket sizes is simply the sheer number of sizes available. From tiny 1/4" drive sockets to hefty 1" drive sockets, the range can be overwhelming. Furthermore, understanding the different drive sizes (the square recess in the socket that attaches to the ratchet or wrench) adds another layer of complexity. This guide will break down the different drive sizes and their corresponding socket sizes, making it easier to choose the right combination for any task. We'll cover common SAE socket sets and help you identify the essential sizes you'll need for various projects.

Having the correct list of SAE socket sizes is crucial for any mechanic or DIY enthusiast. Imagine needing a 10mm socket but only having SAE sizes available. The project grinds to a halt. Having a comprehensive SAE socket set ensures you're prepared for a wide range of tasks, from automotive repairs to home improvement projects.

One benefit of familiarizing yourself with an SAE socket chart is improved efficiency. No more time wasted rummaging through a disorganized toolbox searching for the correct size. You'll quickly identify and select the right tool, saving you valuable time and effort.

Another advantage is preventing damage to fasteners. Using the incorrect socket size can lead to stripped bolts, rounded corners, and other frustrating issues. A clear understanding of SAE socket sizes helps you avoid these costly mistakes and ensures a smooth, efficient workflow.

Lastly, mastering SAE socket sizes empowers you to tackle projects with confidence. Knowing you have the right tools and the knowledge to use them effectively boosts your confidence and allows you to approach any task with a sense of preparedness.

Advantages and Disadvantages of Using SAE Sockets

| Advantages | Disadvantages |

|---|---|

| Widely available in North America | Not as globally standardized as metric |

| Long-established standard in many industries | Can be confusing for those accustomed to metric |

Tips and Tricks for Working with SAE Sockets:

Keep your sockets organized. Use a socket organizer or tray to keep your sockets sorted by size and easily accessible.

Use the appropriate drive size. Don't try to force a larger drive socket onto a smaller drive ratchet.

Apply steady pressure. Avoid jerking or twisting the socket, which can damage the fastener or the socket itself.

In conclusion, understanding SAE socket sizes is a fundamental skill for anyone working with fasteners. From basic home repairs to complex automotive projects, having the right socket for the job is essential. This comprehensive guide has provided you with a solid foundation in SAE socket sizes, from the history and importance of standardization to practical tips, benefits, and real-world examples. By mastering this knowledge, you'll not only increase your efficiency and effectiveness but also gain the confidence to tackle any project that comes your way. So, take the time to familiarize yourself with the information provided, organize your toolbox, and get ready to conquer your next project with confidence.

Socket Sizes In Order Standard - Trees By Bike

Socket Size Chart Socket Sizes In Order From Smallest To 47 OFF - Trees By Bike

Printable Socket Size Chart - Trees By Bike

Conversion Chart Metric To Sae - Trees By Bike

Printable Socket Size Chart - Trees By Bike

Printable Socket Size Chart - Trees By Bike

SAE Socket Sizes for 14 Drive Chart - Trees By Bike

Printable Socket Size Chart Metric And Standard - Trees By Bike

Standard Size Socket Chart at Paul Byrd blog - Trees By Bike

Sae Standard Socket Sizes at Tom Fallon blog - Trees By Bike

Standard Socket Dimensions at Robert Ruiz blog - Trees By Bike

Imperial To Metric Sockets at Thomas Noble blog - Trees By Bike

Sae Standard Socket Sizes at Tom Fallon blog - Trees By Bike

Torque Wrench Conversion Table at Katherine Rowley blog - Trees By Bike

Wrench Conversion Chart For SAE Metric Sizes W Bolt Diameter Guide - Trees By Bike