Ever wondered about those cryptic symbols on your heating system or industrial equipment? Chances are, you've encountered a differential temperature switch symbol without even realizing it. These seemingly small components play a crucial role in maintaining safe and efficient operation in a wide range of applications, from household appliances to complex industrial processes. This guide will demystify the differential temperature switch symbol and explore its significance in the world of temperature control.

So, what exactly is a differential temperature switch? It's a device designed to activate or deactivate a circuit based on the difference between two temperatures. Unlike a thermostat, which reacts to a single temperature point, a differential temperature switch monitors the temperature gap between two locations or substances. This makes it particularly useful in systems where maintaining a specific temperature difference is critical, such as solar heating, refrigeration, and engine cooling.

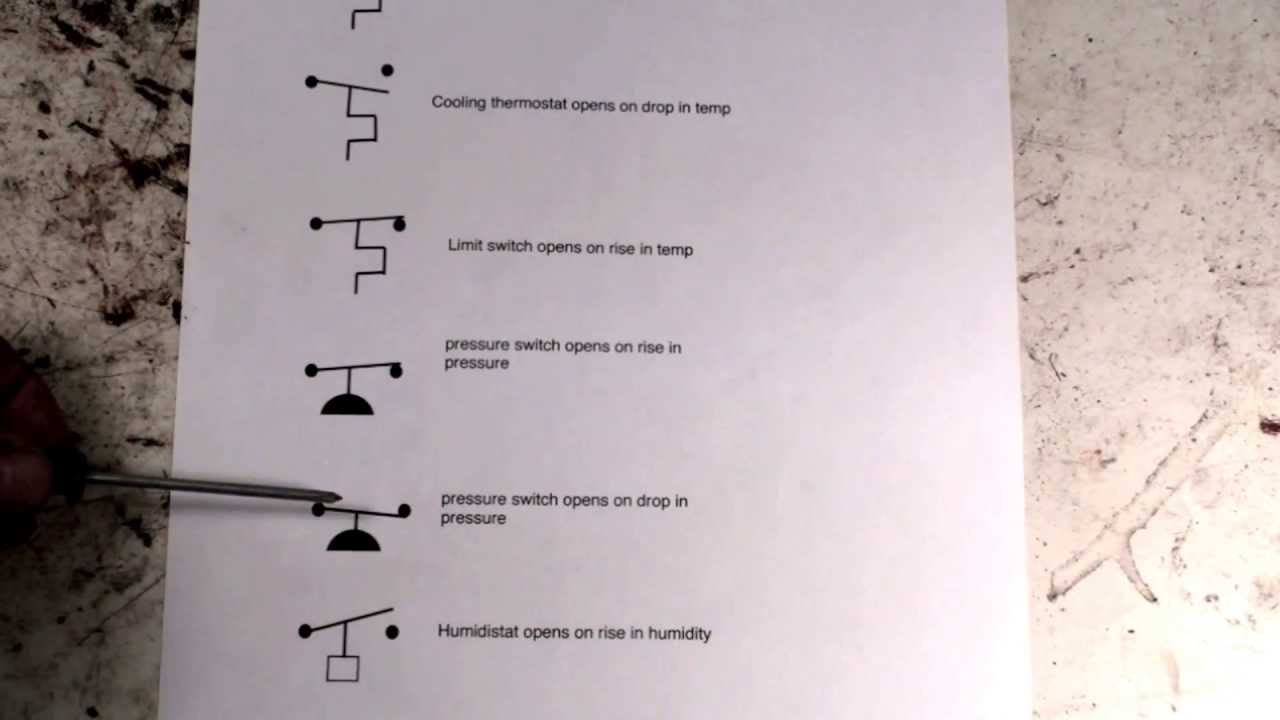

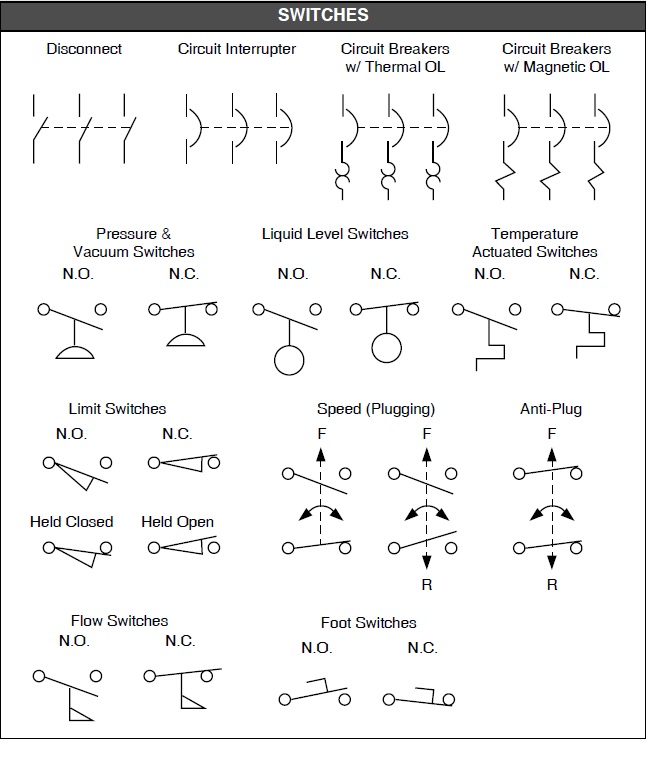

The symbol itself can vary slightly depending on the manufacturer and specific application, but generally features two temperature sensors connected to a switch mechanism. Understanding this symbol is essential for anyone working with these systems, as it provides crucial information about the switch's function and operating parameters. Misinterpreting the symbol can lead to improper installation, malfunction, and potentially hazardous situations. Therefore, a solid understanding of this symbol is crucial for technicians, engineers, and even homeowners.

The historical development of the differential temperature switch symbol parallels the advancement of temperature control technology. As industrial processes became more complex and the need for precise temperature regulation grew, the demand for reliable differential temperature switches increased. This in turn drove the standardization of symbols to facilitate communication and understanding across different industries and regions.

The importance of these switches is underscored by their presence in numerous applications. They protect against overheating in engines, ensure efficient operation in solar thermal systems, and maintain precise temperature differentials in refrigeration units. These are just a few examples of where these switches play a critical role in maintaining safety and efficiency.

A simple example is a solar water heating system. The differential temperature switch monitors the temperature of the water in the solar collector and the temperature of the water in the storage tank. When the temperature difference reaches a predetermined setpoint, the switch activates a pump to circulate the heated water from the collector to the tank. Once the temperature difference drops below the setpoint, the switch deactivates the pump.

One benefit of using a differential temperature switch is enhanced energy efficiency. By only activating a system when a specific temperature difference exists, energy consumption is minimized. Another benefit is improved safety. By monitoring temperature differentials, these switches can prevent overheating and potential damage to equipment. Finally, they contribute to overall system reliability by ensuring consistent and predictable operation.

A typical differential temperature switch symbol shows two temperature sensors connected to a switch element. The symbol often includes markings indicating the switch's operating parameters, such as the temperature difference setpoint and hysteresis.

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Enhanced energy efficiency | Can be more complex to troubleshoot than single-point thermostats |

| Improved safety through overheat protection | Requires careful selection and calibration for optimal performance |

| Increased system reliability | Susceptible to sensor failure, impacting accuracy |

Best Practices:

1. Properly locate the sensors to ensure accurate temperature measurement.

2. Select a switch with an appropriate temperature range and setpoint.

3. Regularly inspect and maintain the switch to ensure reliable operation.

4. Consult the manufacturer's documentation for specific installation and operating instructions.

5. Consider factors like hysteresis and response time when choosing a switch.

Real-world Examples:

1. Solar water heating systems

2. Refrigeration units

3. Engine cooling systems

4. Swimming pool heating systems

5. Industrial process control

FAQs:

1. What is the difference between a differential temperature switch and a thermostat? A thermostat responds to a single temperature, while a differential temperature switch responds to the difference between two temperatures.

2. How do I choose the right differential temperature switch for my application? Consider the required temperature range, setpoint, and hysteresis.

3. Where can I find the symbol for a differential temperature switch? Refer to manufacturer datasheets or industry standards.

4. What are some common problems with differential temperature switches? Sensor failure, improper calibration, and wiring issues.

5. How do I troubleshoot a differential temperature switch? Check the wiring, sensors, and setpoint. Refer to the manufacturer's documentation for troubleshooting guidance.

6. What are the typical operating parameters for a differential temperature switch? This varies depending on the application, but commonly includes the temperature difference setpoint, hysteresis, and operating temperature range.

7. Are differential temperature switches used in residential applications? Yes, common examples include solar water heating and swimming pool heating systems.

8. How can I learn more about differential temperature switches? Consult manufacturer websites, industry publications, and online resources.

Tips and Tricks: Ensure proper sensor placement for accurate readings. Regularly inspect and calibrate the switch for optimal performance. Consult the manufacturer's documentation for specific guidelines.

In conclusion, the differential temperature switch symbol, while seemingly small, represents a critical component in numerous systems. Understanding its function and applications is crucial for ensuring safe and efficient operation in various industries and even in our homes. From preventing engine overheating to maximizing energy efficiency in solar thermal systems, differential temperature switches play a vital role. By familiarizing yourself with the symbol and its associated functionalities, you can better appreciate the importance of this often-overlooked component and its contribution to reliable temperature control. Remember to always consult manufacturer specifications and best practices when working with these switches to ensure optimal performance and safety. Whether you're a technician, engineer, or simply a homeowner, grasping the significance of the differential temperature switch symbol empowers you to make informed decisions about your equipment and maintain its efficient operation. So, the next time you see that symbol, you'll know it represents much more than just a simple switch – it signifies a crucial element in the world of temperature control technology.

Fast Delivery Low Prices Details about Normally Closed Normally - Trees By Bike

Electrical Symbol For Temperature Switch at Scott Kauffman blog - Trees By Bike

Proximity Switch Symbol Pid - Trees By Bike

Selecting the Right Temperature Pressure or Differential Pressure - Trees By Bike

Circuit Diagram Symbol Switch - Trees By Bike

P And Id Diagrams - Trees By Bike

Strain Gauge Symbol at Amanda Morrissey blog - Trees By Bike

Piping Instrumentation Diagrams Tutorials on Pressure Control - Trees By Bike

Air Pressure Switch Electrical Symbol - Trees By Bike

Electrical Schematic Symbols Pressure Switch - Trees By Bike

differential temperature switch symbol - Trees By Bike

differential temperature switch symbol - Trees By Bike