Ever glanced at your gas gauge and felt a pang of uncertainty? Is it really that low, or is your fuel sender playing tricks? A faulty fuel sender unit can lead to inconvenient surprises, from unexpected stops at the gas station to range anxiety on long drives. Understanding how to test this crucial component can save you from these headaches and empower you to take control of your fuel situation.

Testing a fuel sender unit isn't as daunting as it might sound. With a little know-how and some basic tools, you can diagnose fuel gauge inaccuracies and determine if the sender unit is the culprit. This guide will walk you through the process, from understanding the function of the fuel sender unit to troubleshooting common issues.

The fuel sender unit is a relatively simple device with a big job. It sits inside your fuel tank, measuring the fuel level and sending that information to your dashboard gauge. Think of it as the messenger between your fuel tank and your car's brain. Over time, these units can wear out, malfunction, or become clogged with debris, leading to inaccurate fuel level readings.

Historically, fuel senders were purely mechanical, relying on floats and levers to measure fuel. Modern vehicles often utilize electronic sensors, which offer greater precision and durability. However, regardless of the type, the core function remains the same: to accurately report the amount of fuel in the tank. The importance of a functioning fuel sender unit is clear – it keeps you informed about your fuel reserves, preventing unexpected empty tanks and allowing you to plan your journeys effectively.

One of the main issues related to testing a fuel sender is accurately isolating the problem. The fuel gauge itself could be faulty, or the wiring between the sender and the gauge could be damaged. This guide will help you distinguish between these possibilities and pinpoint the source of the issue.

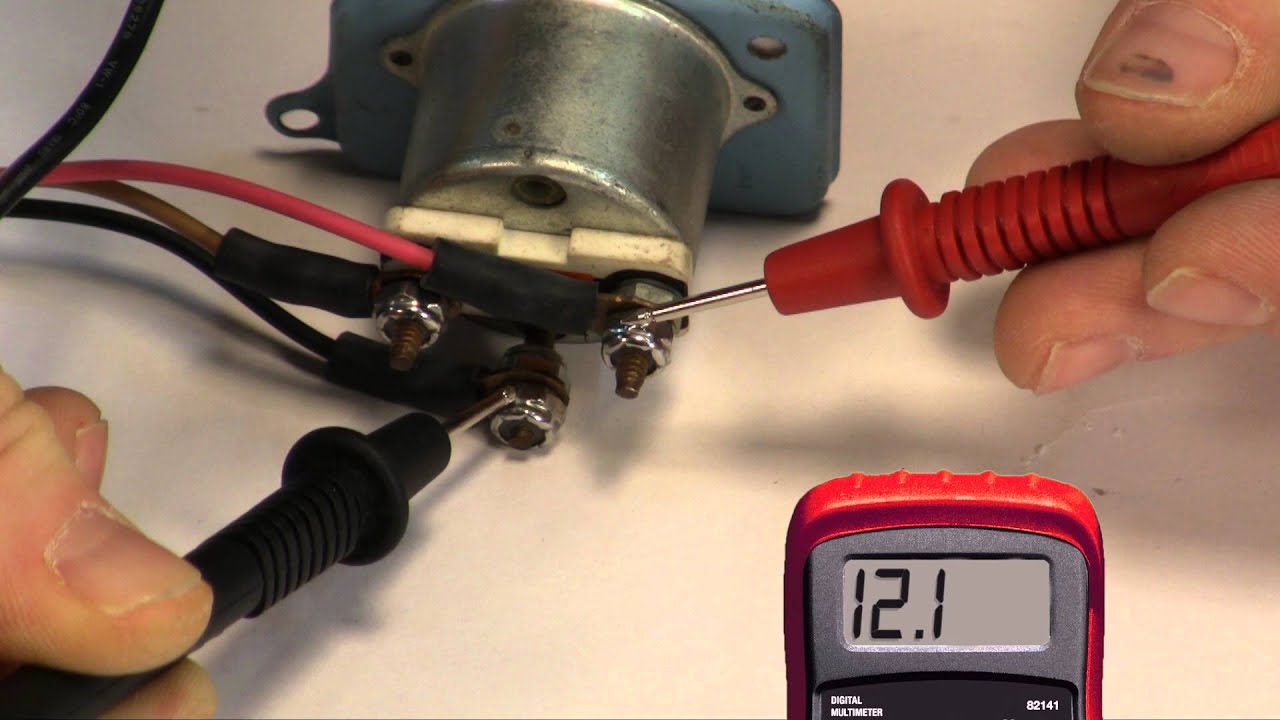

A simple test involves monitoring the fuel gauge reading while adding a known quantity of fuel to the tank. If the gauge doesn't respond appropriately, it could indicate a problem with the sender unit, the wiring, or the gauge itself. A more direct method is to test the resistance of the sender unit using a multimeter. By measuring the resistance at different fuel levels, you can determine if the sender is functioning correctly.

Three benefits of testing your fuel sender unit include: avoiding running out of fuel unexpectedly, saving money by avoiding unnecessary fill-ups, and potentially identifying a larger problem with your fuel system early on. For example, if your fuel gauge reads empty when the tank is half full, you could be wasting money on frequent, unnecessary trips to the gas station.

To test your fuel sender, you'll need a few basic tools, like a multimeter and possibly a fuel tank access panel. Before starting, consult your vehicle's service manual for specific instructions and safety precautions related to working with your fuel system.

While specific procedures may vary depending on your vehicle, the general steps for testing a fuel sender unit often involve accessing the sender unit, disconnecting the wiring harness, and measuring the resistance using a multimeter. Comparing these readings to the manufacturer's specifications can help determine if the unit is functioning within the expected range.

Common challenges include accessing the fuel sender unit, which may require removing part of the vehicle's interior or an access panel under the rear seat. Another challenge is interpreting the multimeter readings correctly, which requires understanding the relationship between resistance and fuel level for your specific vehicle model.

FAQ: What if my fuel gauge is erratic? How do I access the fuel sender unit on my specific vehicle? What tools do I need to test the fuel sender unit? What does a specific resistance reading indicate? Can a bad fuel sender damage other components? What are the signs of a failing fuel sender unit? How much does it cost to replace a fuel sender unit? How can I prevent future fuel sender problems?

A tip for testing your fuel sender unit is to have a helper observe the fuel gauge while you manipulate the float arm or adjust the fuel level. This can help you confirm that the gauge is responding correctly to changes in the sender unit's output.

Understanding how to test your fuel sender unit empowers you to take control of your vehicle's fuel system and avoid the frustration and inconvenience of inaccurate fuel gauge readings. By following the steps outlined in this guide, you can diagnose problems early, potentially saving yourself from unexpected breakdowns and unnecessary expenses. Regular maintenance and timely testing of your fuel sender unit contribute to the overall reliability and efficiency of your vehicle, ensuring smooth and worry-free journeys.

How To Test Fuel Gauge And Sender - Trees By Bike

3 Wire Fuel Sending Unit Wiring Diagram - Trees By Bike

How To Test Fuel Gauge Sending Unit - Trees By Bike

Gm Fuel Sending Unit Wiring Diagram - Trees By Bike

How To Test Fuel Gauge And Sender - Trees By Bike

Chevy Temperature Sender Wiring Diagrams Automotive - Trees By Bike

Schematics For Mercury Trim Wiring Switch - Trees By Bike

Wiring A Fuel Gauge - Trees By Bike

How To Remove Fuel Bowl 73 1997 at Jonathan Little blog - Trees By Bike

1980 Chevrolet Truck Fuel Switch Wiring - Trees By Bike

Replacing Fuel Sending Unit - Trees By Bike

Trouble Shooting Gauges in 2024 - Trees By Bike

How To Test Fuel Gauge And Sender - Trees By Bike

IN TANK FUEL PUMP SENDER UNIT FOR RANGE ROVER L322MK3 30 TD6 - Trees By Bike

how to test fuel sender unit - Trees By Bike