Ever wondered how your sump pump knows when to turn on or off? Or how your water tank avoids overflowing? The answer often lies with a small but mighty device: the float switch. These ingenious level sensors are essential components in various systems, acting as the brains behind liquid level control. This article dives deep into the world of float switches, focusing on the crucial distinction between normally open and normally closed configurations.

Float switches, sometimes called level switches, are simple yet effective devices used to detect the level of liquid within a tank or other container. They work based on buoyancy. A sealed, hollow float containing air rises and falls with the liquid level, activating a switch at a predetermined point. This switch then triggers an action, such as turning a pump on or off, activating an alarm, or closing a valve.

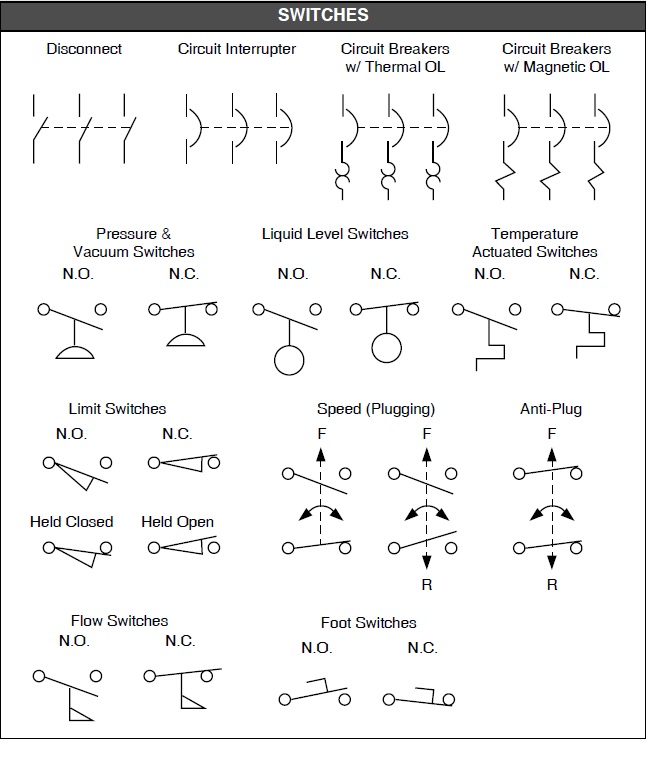

The critical difference lies in the switch's default state. A normally open (NO) float switch has an open circuit in its resting position. When the float rises to a specific level, the circuit closes, allowing current to flow and triggering the connected device. Conversely, a normally closed (NC) float switch has a closed circuit in its resting position. When the float rises, the circuit opens, interrupting the current and triggering the connected device. Choosing the correct type depends entirely on the specific application.

The origins of float switches can be traced back to basic mechanical float valves used for centuries in applications like toilet cisterns. The modern electrical float switch evolved from these simpler devices, incorporating electrical circuitry to provide more sophisticated control and automation. Today, float switches are indispensable in countless industries, from wastewater management and manufacturing to agriculture and domestic appliances.

One of the main issues surrounding float switches is selecting the correct configuration—normally open or normally closed—for a particular application. Using the wrong type can lead to system malfunctions, overflows, or pump damage. Other common issues include debris buildup interfering with the float's movement, switch failure due to corrosion or wear and tear, and incorrect wiring. Understanding these potential problems and implementing appropriate preventative measures is essential for ensuring reliable operation.

For example, imagine a sump pump designed to remove excess water. A normally open float switch would be appropriate here. As the water level rises, the float rises, closing the circuit and activating the pump. When the water level drops, the float falls, opening the circuit and turning the pump off. Conversely, a high-level alarm in a water tank would require a normally closed float switch. The closed circuit in the normal state keeps the alarm off. If the water level rises too high, the float rises, opening the circuit and triggering the alarm.

Three key benefits of using float switches are automation, safety, and efficiency. Automation eliminates the need for manual monitoring and intervention, freeing up human resources. Safety features, such as high-level alarms, prevent potentially hazardous situations like overflows or equipment damage. Efficiency is improved by automating processes like pump control, optimizing energy consumption and reducing wear and tear on equipment.

Choosing the right float switch involves considering factors like liquid type, tank size and shape, switching current and voltage requirements, and operating environment. Accurate specifications ensure optimal performance and prevent premature failure. Regularly inspecting and cleaning the float switch, checking for debris buildup and signs of wear, are crucial for maintaining its functionality.

Advantages and Disadvantages of Normally Open and Normally Closed Float Switches

| Feature | Normally Open (NO) | Normally Closed (NC) |

|---|---|---|

| Default State | Open Circuit | Closed Circuit |

| Action on Rising Float | Closes Circuit | Opens Circuit |

| Typical Use | Activating a device (e.g., pump) | Deactivating a device or triggering an alarm |

| Fail-Safe in Power Outage | Depends on application (pump off) | Depends on application (alarm off) |

Five best practices for implementing float switches include selecting the correct type (NO or NC), ensuring proper wiring and electrical connections, choosing materials compatible with the liquid being monitored, regularly inspecting and cleaning the switch, and installing the switch at the correct height for the desired activation point.

Real-world examples of float switch applications include sump pumps, sewage lift stations, water tanks, industrial process control, and even coffee machines.

Challenges related to float switches can include turbulent liquid causing false activations, debris buildup hindering float movement, and corrosion due to harsh chemicals. Solutions involve using specialized floats for turbulent environments, regular cleaning and maintenance, and selecting corrosion-resistant materials.

FAQs include: What is a float switch? How does a float switch work? What is the difference between normally open and normally closed? How do I choose the right float switch? How do I install a float switch? How do I troubleshoot a float switch? What are the common problems with float switches? How do I maintain a float switch?

Tips and tricks include using a strainer to prevent debris buildup, checking the switch's voltage rating, and testing the switch regularly to ensure proper operation.

In conclusion, float switches, whether normally open or closed, are essential components in numerous applications requiring liquid level control. Understanding their operation, different configurations, and potential challenges is crucial for implementing and maintaining these devices effectively. From simple household appliances to complex industrial systems, float switches offer a reliable and cost-effective solution for automating processes, enhancing safety, and optimizing efficiency. By following best practices and addressing potential issues proactively, you can ensure the long-term reliability and optimal performance of your float switch system. Investing time in understanding these small but powerful devices will undoubtedly pay off in the long run. Choose wisely, install correctly, and maintain regularly for a smooth and efficient operation.

Cable Float Switch NONC 23510 Mtr Cable Lenght - Trees By Bike

Float Switch Normally Open 15 Foot Cord - Trees By Bike

Normally Open Switch Symbol - Trees By Bike

The Ultimate Guide to Understanding the Float Switch Schematic Symbol - Trees By Bike

Everbilt Normally Closed Float Switch - Trees By Bike

Open And Closed Switch - Trees By Bike

electrical diagram symbols normally open switch - Trees By Bike

Normally open NO contactswitch Electrical Switches Electrical - Trees By Bike

Pump Duty Avocado Float Switch - Trees By Bike

Pressure Switch Schematic Symbol - Trees By Bike

float switch normally open or closed - Trees By Bike

Pump Duty Float Switch - Trees By Bike

float switch normally open or closed - Trees By Bike

Qué es este símbolo electrónico - Trees By Bike

Electrical Symbols For Switches And Outlets - Trees By Bike