Imagine this: a perfect sunset, the gentle lapping of waves against your dock, and your boat… stuck halfway in the water because of a faulty boat lift switch. Frustrating, right? Understanding the intricacies of your Bremas boat lift switch wiring can prevent such scenarios and ensure your boat is always ready for your next adventure.

Wiring a Bremas boat lift switch might seem daunting, but with a little patience and the right guidance, it can be a manageable task. This article aims to demystify the process, providing you with a comprehensive understanding of everything from the basic principles to advanced troubleshooting techniques. We’ll delve into the history and significance of proper switch wiring, explore common issues, and provide a practical roadmap for successful installation.

The importance of correctly connecting a Bremas boat lift switch cannot be overstated. It’s the critical link between your power source and the lift motor, controlling the raising and lowering of your boat. Faulty wiring can lead to anything from inconvenient malfunctions to dangerous electrical hazards. Therefore, a thorough understanding of the wiring process is essential for both the safety and functionality of your boat lift.

Let’s dive into a bit of history. Bremas switches, known for their durability and reliability, have become a staple in the boating world. Their design evolved alongside the increasing complexity of boat lift systems, reflecting the need for robust and user-friendly control mechanisms. This evolution has led to a variety of Bremas switch models, each designed for specific applications and load capacities. Understanding the specific model you’re working with is crucial for proper wiring.

One of the main issues encountered when wiring a Bremas boat lift switch is incorrect wire identification and connection. Miswiring can lead to motor malfunction, blown fuses, or even damage to the lift system itself. Another common problem is neglecting the grounding system, which can create safety hazards and compromise the switch's longevity. We'll address these issues head-on, offering clear solutions and preventative measures.

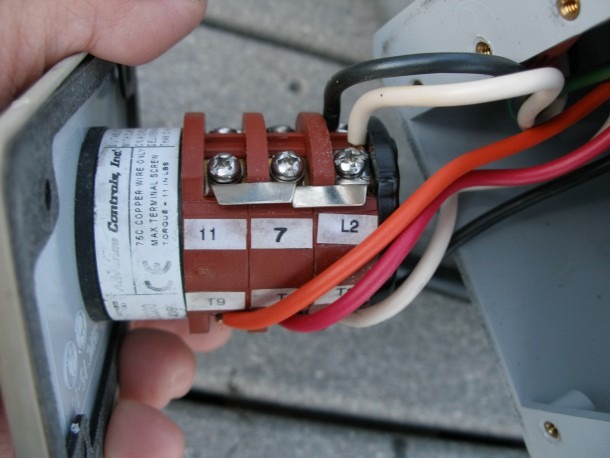

Before starting any electrical work, ensure the power to the boat lift is disconnected. Identify the wires coming from the power source and the wires leading to the lift motor. Consult the wiring diagram specific to your Bremas switch model. Typically, you'll have wires for power in, power out to the motor (up and down), and a ground wire.

Benefits of Properly Wiring a Bremas Boat Lift Switch:

1. Safety: Correct wiring eliminates the risk of electrical shocks and short circuits, protecting both you and your equipment.

2. Reliability: A properly wired switch ensures smooth and consistent operation of your boat lift, minimizing downtime and frustration.

3. Longevity: Accurate wiring prevents damage to the switch and motor, extending the lifespan of your boat lift system.

Best Practices:

1. Always disconnect power before working on any electrical components.

2. Use marine-grade wiring and connectors designed for outdoor environments.

3. Consult the wiring diagram specific to your Bremas switch model.

4. Secure all wiring connections with appropriate wire nuts or crimp connectors.

5. Test the switch operation thoroughly after completing the wiring.

Frequently Asked Questions:

1. Where can I find the wiring diagram for my Bremas switch? (Check the manufacturer's website or contact their customer support.)

2. What type of wire should I use? (Marine-grade wire suitable for the amperage of your boat lift motor.)

3. Do I need to ground the switch? (Yes, grounding is crucial for safety.)

4. What should I do if the motor doesn't run after wiring the switch? (Double-check all connections and ensure the power is on.)

5. Can I wire the switch myself, or should I hire a professional? (If you're comfortable with basic electrical work, you can do it yourself. Otherwise, consult a qualified electrician.)

6. How do I troubleshoot a malfunctioning Bremas switch? (Check for loose connections, blown fuses, or damage to the switch itself.)

7. What are the signs of a faulty boat lift switch? (Intermittent operation, overheating, or sparking.)

8. Where can I buy replacement parts for my Bremas switch? (Marine supply stores or online retailers.)

Conclusion

Mastering the wiring of your Bremas boat lift switch is a crucial step towards ensuring the smooth, safe, and reliable operation of your boat lift. By understanding the fundamental principles, following best practices, and addressing potential challenges proactively, you can enjoy countless hassle-free boating experiences. Proper wiring not only protects your investment but also enhances safety, providing peace of mind knowing your boat lift is functioning correctly. While this article offers a comprehensive guide, remember to always consult the specific wiring diagram for your Bremas switch model and seek professional assistance if needed. Don't let a faulty switch keep you landlocked – take control and ensure your boat is always ready for the open water.

Bremas Drum Switch with Wiring Harness - Trees By Bike

Boat Lift Switch Wiring Diagram - Trees By Bike

I am hooking up s Bremas switch to a new boat lift motor and need help - Trees By Bike

how to wire a bremas boat lift switch - Trees By Bike

Boat Lift Switch Wiring Diagram - Trees By Bike

Ao Smith Wiring Diagrams - Trees By Bike

Bremas Boat Lift Switch Wiring Diagram Collection - Trees By Bike

Boat Lift Drum Switch Wiring Diagram - Trees By Bike

Boat Lift Motor And Switch - Trees By Bike

How To Wire A Boat Lift Switch - Trees By Bike

Wiring Diagram For Salzer Boat Lift Switch - Trees By Bike

Boat Lift Switch Wiring Diagram Picture - Trees By Bike

Boat Lift Drum Switch Wiring Diagram - Trees By Bike

Bremas Boat Lift Switch Wiring Diagram - Trees By Bike

Wire Bremas Switch To Replacement Boat Lift Motor DIY Home 48 OFF - Trees By Bike