Adding a 100 amp subpanel is a common upgrade for homeowners needing more electrical circuits. Whether you're powering a workshop, a new addition, or simply expanding your home's electrical capacity, getting the wire size right is paramount. Choosing the incorrect wire gauge for a 100 amp subpanel can lead to overheating, voltage drop, and even fire hazards. This comprehensive guide will walk you through everything you need to know about selecting the proper conductor size for your project.

Understanding the relationship between amperage, wire gauge, and distance is essential. Amperage is the amount of electrical current flowing through the wire, while wire gauge refers to the wire's thickness. A lower gauge number indicates a thicker wire capable of carrying more current. The distance the wire runs also plays a role; longer runs require thicker wires to minimize voltage drop, which is the reduction in voltage as electricity travels along the wire.

Historically, wire gauges were determined by the number of drawing dies used to create the wire. The more times the wire was drawn through a die, the thinner it became and the higher the gauge number. Today, standardized charts and calculations provide precise guidance for selecting the correct wire gauge. The importance of choosing the correct wire gauge for a 100 amp subpanel cannot be overstated. An undersized wire will overheat, potentially causing insulation to melt and creating a fire hazard. Conversely, an oversized wire is unnecessarily expensive and can be difficult to work with.

The primary issue associated with incorrect wire gauge selection for a 100 amp subpanel is safety. Overheating wires are a significant fire risk and can damage connected equipment. Another concern is voltage drop. If the voltage drop is excessive, appliances and devices may not function properly, and motors can overheat and fail prematurely.

For a 100 amp subpanel, the recommended wire size is typically #3 AWG copper or #1 AWG aluminum. This recommendation is based on the National Electrical Code (NEC) and considers standard installation conditions. However, factors like ambient temperature and the length of the wire run can influence the appropriate size. Always consult the NEC and local building codes for definitive guidance. Using a wire size calculator, available online and in electrical supply stores, can help you determine the precise wire size needed for your specific situation.

One benefit of using the correct wire size is safety. Preventing overheating and fire hazards is crucial. Another advantage is ensuring optimal appliance and device performance by minimizing voltage drop. Finally, proper wire sizing ensures compliance with electrical codes and regulations, which is essential for inspections and insurance coverage.

Planning your subpanel installation involves determining the location, calculating the load, and selecting the correct wire gauge and breaker size. Successfully installing a subpanel requires careful planning and adherence to safety guidelines. Consult a qualified electrician if you are unsure about any aspect of the installation process.

Advantages and Disadvantages of Different Wire Materials

| Material | Advantages | Disadvantages |

|---|---|---|

| Copper | Excellent conductivity, corrosion resistant, easier to work with | More expensive than aluminum |

| Aluminum | Lighter and less expensive than copper | Requires special connectors and anti-oxidant paste, more susceptible to corrosion |

Best practices include consulting the NEC and local codes, using a wire size calculator, ensuring proper grounding and bonding, using appropriate connectors, and protecting the wires from physical damage.

Common challenges include dealing with long wire runs, working in tight spaces, and ensuring proper grounding. Solutions include using larger gauge wire for long runs, employing specialized tools for tight spaces, and using grounding rods and connectors according to code.

Frequently Asked Questions:

Q: What if my run is longer than 100 feet? A: Consult a wire size calculator or an electrician to determine the appropriate wire gauge for longer runs.

Q: Can I use aluminum wire for a 100 amp subpanel? A: Yes, but you must use connectors rated for aluminum wire and apply anti-oxidant paste.

Q: Do I need a permit for installing a subpanel? A: Yes, in most jurisdictions, a permit is required.

Q: What type of conduit should I use? A: Consult your local electrical code for approved conduit types.

Q: Can I install the subpanel myself? A: While possible, it's recommended to hire a qualified electrician, especially if you are not experienced with electrical work.

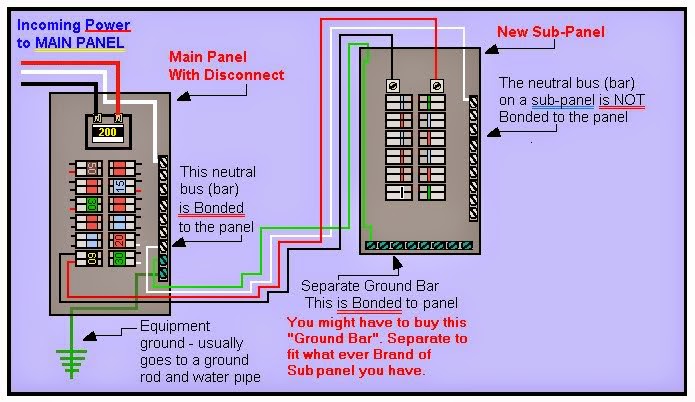

Q: What is the difference between a main panel and a subpanel? A: A main panel receives power directly from the utility company, while a subpanel receives power from the main panel.

Q: What is the purpose of a ground wire? A: The ground wire provides a path for fault currents to flow back to the source, protecting people and equipment.

Q: How do I calculate the load for my subpanel? A: Add up the wattage of all the devices you plan to connect to the subpanel.

Tips and tricks include using a fish tape for pulling wire through conduit, labeling wires clearly, and double-checking all connections.

In conclusion, selecting the right wire gauge for your 100 amp subpanel is a crucial step in ensuring a safe and efficient electrical system. While #3 AWG copper or #1 AWG aluminum are common recommendations, various factors, such as distance and ambient temperature, can influence the final decision. Always refer to the National Electrical Code and local building codes for precise guidelines. By carefully calculating your load requirements and choosing the correct wire size, you'll prevent potential hazards like overheating and voltage drop, ultimately safeguarding your home and ensuring the optimal performance of your electrical appliances. Remember, consulting with a qualified electrician is always a wise choice, especially for complex electrical projects. Don't compromise on safety – take the time to get it right the first time. Investing in proper wiring now will save you headaches and potential dangers down the road.

what gauge wire for 100 amp sub panel - Trees By Bike

What Size Wire For 60 Amp Subpanel - Trees By Bike

What Size Ground Wire For 100 Amp Sub Panel - Trees By Bike

Wiring Diagram For 60 Amp Subpanel - Trees By Bike

Sub Panel 100 Amp Wire Size - Trees By Bike

Wire Size For 30 Amp Sub Panel - Trees By Bike

70 Amp Sub Panel Wiring - Trees By Bike

Square D 100 Amp Sub Panel Wiring Diagram - Trees By Bike

what gauge wire for 100 amp sub panel - Trees By Bike

100 Amp Sub Panel Wiring - Trees By Bike

100 amp service panel wire size - Trees By Bike

Electrical Wire Size For Sub Panel at Valerie Parker blog - Trees By Bike

Electrical Wire For 100 Amp Sub Panel - Trees By Bike

Ground Wire Size For 60 Amp Subpanel - Trees By Bike

Wire Size For 200 Amp Panel - Trees By Bike