In the intricate tapestry of electrical engineering, there exist unsung heroes, silently orchestrating the flow of power that fuels our modern world. These are the contactors and relays, the quiet guardians of our electrical circuits. Their seemingly simple mechanism belies a profound impact on everything from industrial automation to household appliances.

Imagine a world without the ability to remotely control high-voltage circuits. The very infrastructure of our society, from power grids to manufacturing plants, relies on the seamless switching provided by these electromechanical marvels. Contactors and relays act as intermediaries, allowing low-voltage signals to control significantly larger currents, safeguarding both equipment and human operators.

The story of contactors and relays begins in the 19th century with the development of the telegraph and the growing need to manage electrical signals across long distances. Early relays were simple electromagnetic switches, using a small current to activate a larger one. This fundamental principle remains at the core of their operation today, albeit with significant advancements in materials and design.

The distinction between a relay and a contactor lies primarily in their current-handling capacity. Relays typically handle smaller currents, often used in control circuits and electronic devices. Contactors, on the other hand, are designed for heavier loads, commonly employed in industrial applications to control motors, lighting systems, and other high-power equipment. Both, however, utilize the same basic principle of electromagnetic switching.

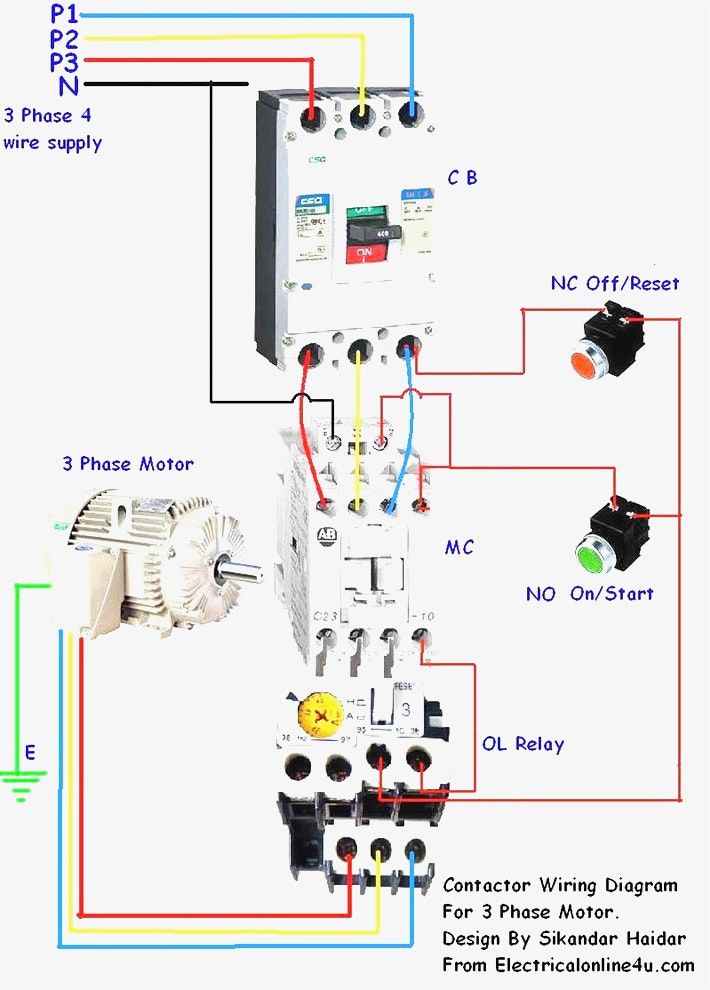

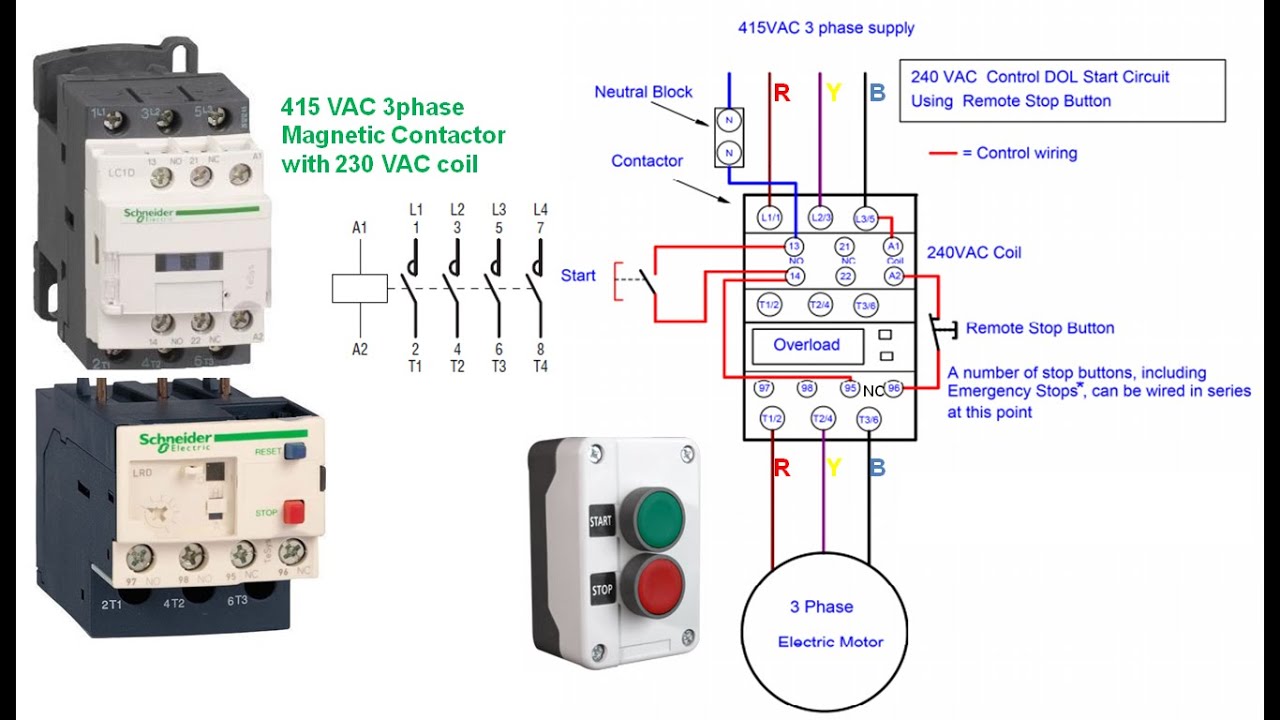

A crucial aspect of understanding contactor and relay functionality is the concept of the control circuit and the power circuit. The control circuit, operating at a lower voltage, activates the electromagnet within the device. This energized electromagnet then closes the contacts within the power circuit, allowing the high-voltage current to flow through and complete the intended action, be it starting a motor or illuminating a bank of lights.

A key advantage of using contactors and relays is electrical isolation. By separating the control and power circuits, these devices protect operators from high voltages, enhancing safety. Furthermore, they enable remote operation, allowing control from a distance, and automated switching, facilitating complex control sequences in industrial processes. Finally, they offer overload protection, preventing damage to equipment by interrupting the circuit in case of excessive current flow.

Implementing contactors and relays requires careful consideration of factors such as load current, voltage ratings, and environmental conditions. Selecting the appropriate device is crucial for ensuring reliable and safe operation. Furthermore, proper wiring and maintenance are essential to prevent malfunctions and ensure longevity.

Real-world examples of contactor and relay applications abound. In a manufacturing facility, contactors control the operation of powerful motors driving assembly lines. In our homes, relays are at work in appliances like refrigerators and washing machines, controlling various functions. Even in the automotive industry, relays play a vital role in managing everything from headlights to windshield wipers.

Advantages and Disadvantages of Contactors and Relays

While contactors and relays offer numerous benefits, they also have some limitations.

Common challenges include contact wear, arc formation, and sensitivity to environmental factors like temperature and humidity. Regular inspection and maintenance are essential to mitigate these issues and ensure optimal performance.

For instance, contact bounce, a phenomenon where the contacts momentarily open and close multiple times during switching, can be problematic in certain applications. Solutions include using specialized contact materials or incorporating debouncing circuits to eliminate the unwanted oscillations.

FAQ: What is the difference between a contactor and a relay? A contactor is designed for higher currents than a relay. What are the main applications of contactors? Contactors are commonly used in industrial settings for controlling motors and other high-power equipment. How do I select the right contactor for my application? Consider factors like voltage, current, and the type of load being switched. What are some common problems with contactors? Contact wear, arc formation, and coil burnout are potential issues. How can I troubleshoot a contactor problem? Check for loose connections, test the coil voltage, and inspect the contacts for wear or damage. What are the benefits of using relays in electronic circuits? Relays provide electrical isolation, enable remote control, and offer overload protection. How do I wire a relay? Consult the relay's datasheet for the specific wiring diagram. What is the lifespan of a contactor or relay? The lifespan depends on factors like usage, environment, and maintenance but typically ranges from several years to decades.

Tips for working with contactors and relays: Always disconnect power before working on any electrical circuit involving these devices. Use appropriate safety precautions, including wearing insulated gloves and eye protection. Consult the manufacturer's specifications for proper installation and maintenance procedures. Regularly inspect contacts for wear and tear. Ensure proper ventilation to prevent overheating. Choose devices with appropriate ratings for the intended application.

In conclusion, contactors and relays, though often overlooked, form an integral part of our electrified world. Their ability to control high-power circuits with low-voltage signals has revolutionized industries and simplified countless everyday tasks. From the humming machinery of factories to the quiet operation of our home appliances, these unassuming devices play a vital role in shaping our modern landscape. Understanding their function, benefits, and proper implementation is crucial for anyone working with electrical systems. As we move towards an increasingly automated future, the importance of these silent guardians will only continue to grow. Their quiet hum is the soundtrack of our technological progress, a testament to the ingenuity and elegance of electrical engineering. By continuing to refine and innovate upon these fundamental components, we pave the way for even greater advancements in power control and automation, further solidifying the crucial role of contactors and relays in our electrified world. Explore the world of electrical control and discover the power behind the silence.

How To Wire A Control Relay Contacts - Trees By Bike

Contactor Single Line Diagram - Trees By Bike

contactor and relay connection - Trees By Bike

How To Connect Overload Relay With Contactor - Trees By Bike

How To Wire A Contactor - Trees By Bike

Electronic Overload Relay Circuit Diagram - Trees By Bike

contactor and relay connection - Trees By Bike

Reverse Forward Motor Control Circuit Using ZEN PLC Relay - Trees By Bike

contactor and relay connection - Trees By Bike

contactor and relay connection - Trees By Bike

Wiring 20a 20contactor For Contactor And Overload Wiring Diagr - Trees By Bike

Contactor Single Line Diagram - Trees By Bike

Contactor Switch Wiring Diagram - Trees By Bike

Schematic Diagram Of Magnetic Contactor - Trees By Bike

Phase Controller Wiring Phase Failure Relay Diagram - Trees By Bike