Ever wondered how water gets pressurized to reach the top floors of a building or how a well can consistently deliver water even at significant depths? The answer often lies in the ingenuity of two-stage pumps. These powerful machines play a crucial role in various applications, from residential water supply to industrial processes.

So, what is a two-stage pump? Simply put, a two-stage pump is a type of centrifugal pump that utilizes two impellers connected in series within a single casing. This design allows the pump to generate significantly higher pressure than a comparable single-stage pump. Instead of just one impeller boosting the water pressure, the water passes through two, effectively doubling the pressure boost. Think of it like two stepping stones instead of one, helping the water climb higher.

Understanding the function of a two-stage pump starts with grasping the basic principles of centrifugal pumps. These pumps utilize a rotating impeller to accelerate the fluid radially outward. This acceleration converts kinetic energy into potential energy, manifesting as increased pressure. In a two-stage configuration, the fluid exits the first impeller and enters the second, receiving an additional pressure boost.

Imagine needing to water a garden far from your house. A single-stage pump might struggle to deliver enough pressure for the water to reach. A two-stage pump, however, could easily provide the needed pressure, ensuring your garden thrives. This simple analogy illustrates the core advantage of two-stage pumps: enhanced pressure output.

The evolution of pumping technology from single-stage to two-stage designs reflects a constant pursuit of efficiency and performance. Early pumps relied solely on single impellers, limiting their pressure capabilities. The development of two-stage pumps opened new possibilities, enabling applications requiring higher pressures, such as high-rise buildings and deep wells. These pumps are crucial in various industries, including agriculture, manufacturing, and municipal water supply.

A typical two stage pump consists of a casing, two impellers mounted on a common shaft, and a motor to drive the shaft. The water enters the first impeller, where it receives an initial boost in pressure. It then flows into the second impeller, which further increases the pressure before exiting the pump.

Three key benefits of using a two-stage pump include increased pressure output, improved efficiency at higher pressures, and the ability to handle higher flow rates compared to single-stage pumps for the same pressure. For example, in a well application, a two-stage pump can draw water from deeper depths more efficiently than a single-stage pump.

While not always necessary, a checklist for using a two-stage pump could include ensuring proper priming, checking for leaks, and regularly monitoring motor temperature and pressure gauges.

Advantages and Disadvantages of Two-Stage Pumps

| Advantages | Disadvantages |

|---|---|

| Higher pressure output | More complex design compared to single-stage pumps |

| Improved efficiency at higher pressures | Can be more expensive than single-stage pumps |

| Suitable for deep wells and high-rise buildings | Requires more maintenance |

Five best practices for using two-stage pumps are: 1. Ensure proper priming before operation. 2. Regularly check for leaks. 3. Monitor motor temperature and pressure gauges. 4. Use the correct viscosity of lubricating oil. 5. Schedule regular maintenance checks.

Frequently asked questions about two-stage pumps include: What is the difference between a single-stage and a two-stage pump? What applications are two-stage pumps best suited for? How do I maintain a two-stage pump? What are the common problems associated with two-stage pumps? What are the different types of two-stage pumps available? How do I choose the right two-stage pump for my needs? What are the energy efficiency considerations for two-stage pumps? How does the impeller design affect the performance of a two-stage pump?

A helpful tip for maintaining a two-stage pump is to regularly check the shaft seal for wear and tear.

In conclusion, understanding the function and benefits of two-stage pumps is crucial for various applications requiring higher pressure and flow rates. From providing water to high-rise buildings to extracting water from deep wells, these powerful machines play a vital role in modern life. The two-stage design allows for increased efficiency and performance compared to single-stage pumps, justifying the slightly higher initial cost and maintenance requirements. Choosing the right pump for your specific needs and implementing proper maintenance practices ensures optimal performance and longevity. By understanding the working principles, advantages, and best practices, you can effectively utilize two-stage pumps to meet your water pressure and flow demands, contributing to more efficient and reliable water systems. Remember to consult with a pump specialist to determine the best two-stage pump for your specific application.

what is a two stage pump - Trees By Bike

Edwards E2M8 Two Stage Pump - Trees By Bike

Adjusting Two Stage Hydraulic Pump - Trees By Bike

Schulz Two Stage Air Compressor Pump MSV 20 Max - Trees By Bike

what is a two stage pump - Trees By Bike

what is a two stage pump - Trees By Bike

what is a two stage pump - Trees By Bike

Centrifugal Fire Pump Diagram - Trees By Bike

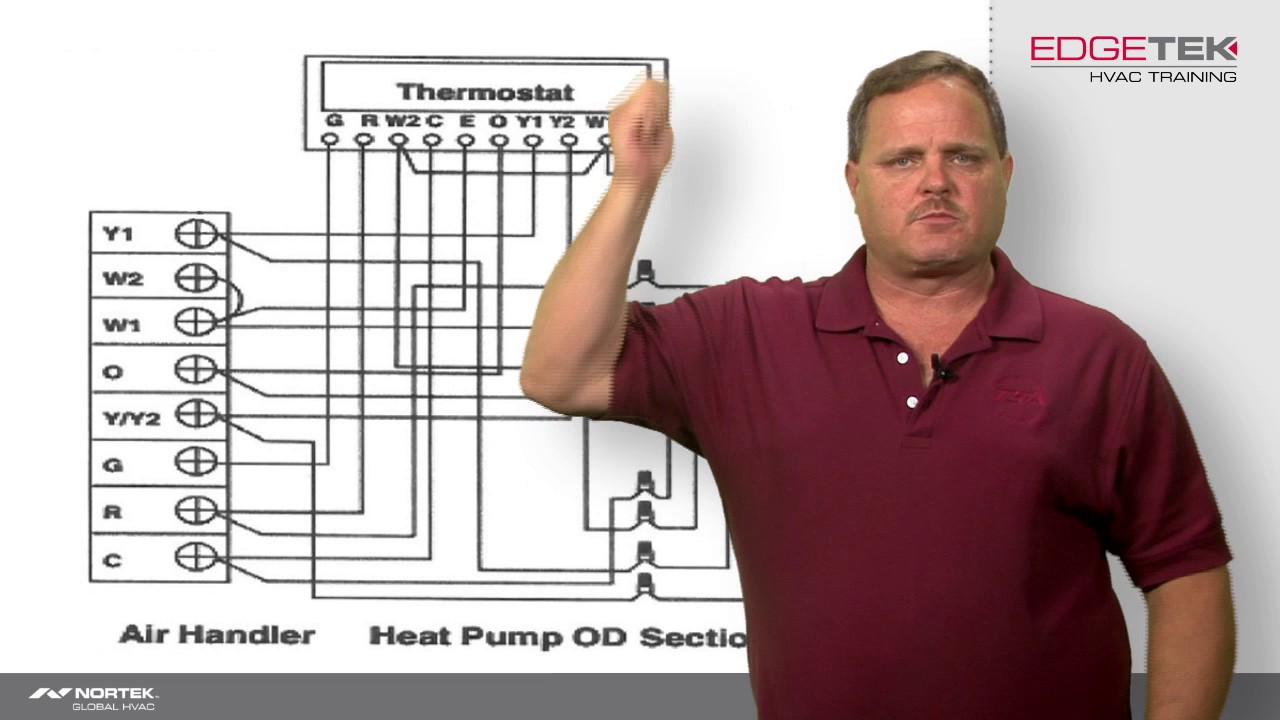

Two Stage Heat Pump - Trees By Bike

what is a two stage pump - Trees By Bike

36 CFM Two Stage Compressor Pump 75 HP - Trees By Bike

2 stage air compressor wholesale price - Trees By Bike

what is a two stage pump - Trees By Bike

what is a two stage pump - Trees By Bike

Two Stage Hydraulic Pump Schematic - Trees By Bike