Ever wondered how to transform simple household items into a miniature speed machine? Building a rubber band powered car is a fantastic way to explore basic physics, engineering principles, and unleash your creativity. It's a hands-on project perfect for all ages, from kids eager to tinker to adults seeking a nostalgic throwback. This guide provides a comprehensive roadmap to designing, building, and optimizing your very own rubber band powered vehicle.

Building a rubber band powered car isn't just about slapping some parts together. It's about understanding the interplay of potential energy stored in the twisted rubber band and its conversion into kinetic energy that propels the car forward. This seemingly simple toy car embodies fundamental physics concepts, offering a tangible learning experience that's far more engaging than textbook diagrams. This DIY project encourages problem-solving and experimentation, as you tweak your design to achieve maximum speed and distance.

The origins of rubber band powered cars can be traced back to the early 20th century, coinciding with the widespread availability of rubber bands. Initially crafted from simple materials like wood and cardboard, these toy cars became a popular pastime for children. Over time, designs evolved, incorporating more sophisticated materials and techniques. Today, rubber band cars are not just toys; they feature in science fairs, engineering competitions, and educational programs, demonstrating the power of simple mechanics.

One of the primary challenges in building a rubber band powered car lies in optimizing energy transfer. Friction is the enemy of efficiency. Minimizing friction between moving parts, such as axles and the car body, is crucial to maximizing the distance your car travels. Choosing the right type of rubber band, ensuring proper winding, and aligning the wheels perfectly are all essential factors contributing to a successful design. Troubleshooting issues like wobbly wheels, slippage, and uneven weight distribution is all part of the learning process.

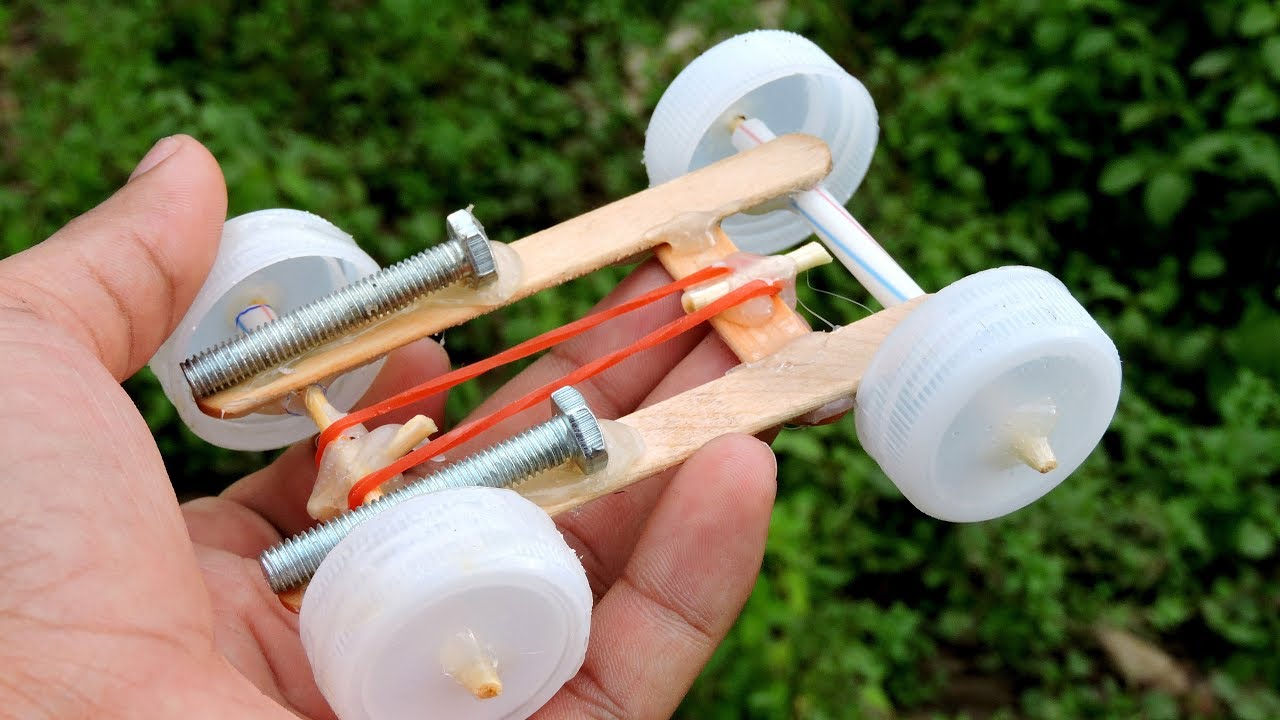

Let's define some key terms: "Potential energy" refers to the stored energy in the stretched rubber band, ready to be released. "Kinetic energy" is the energy of motion as the car moves. "Friction" is the resistance to motion between two surfaces in contact. For example, if your axle rubs against the car body, friction converts some of the kinetic energy into heat, slowing the car down. A simple example of a rubber band car is a small block of wood with axles attached, wheels mounted on the axles, and a rubber band looped around a hook or notch to propel the car forward.

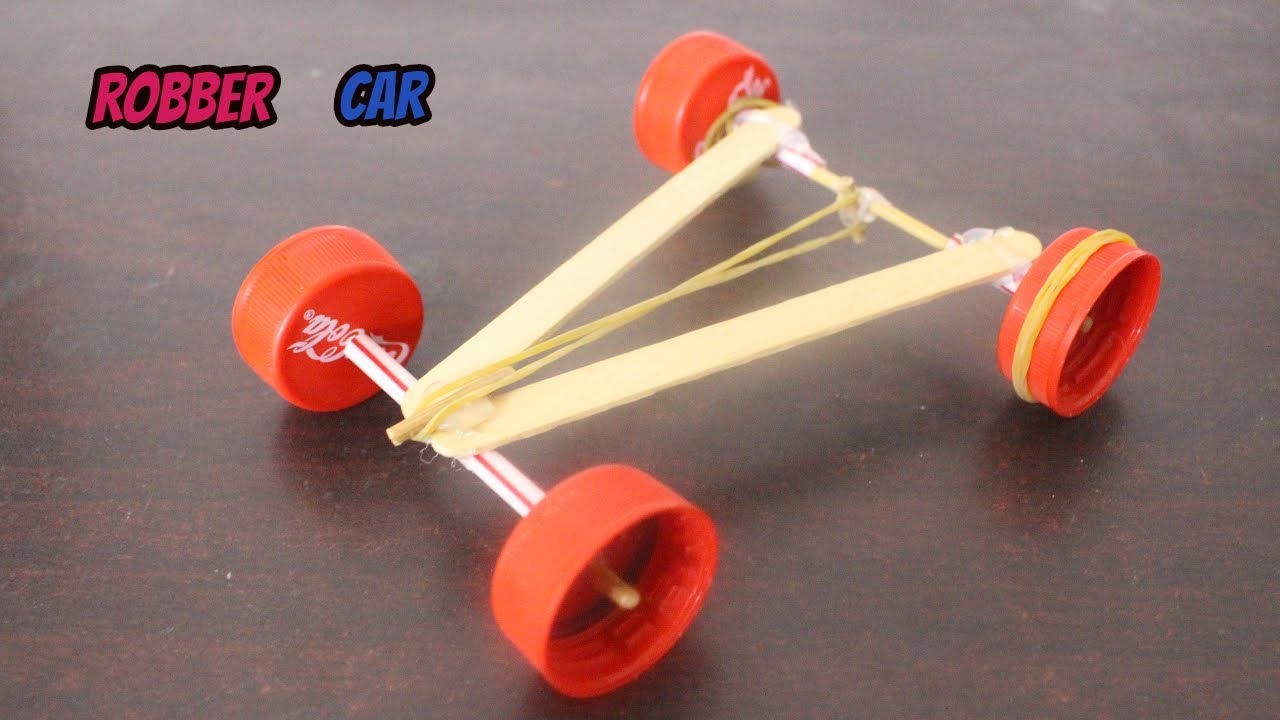

Building a DIY rubber band car offers numerous benefits. Firstly, it's a budget-friendly activity, often using readily available materials like cardboard, wood scraps, straws, and bottle caps. This encourages resourcefulness and reduces reliance on expensive store-bought toys. Secondly, it provides a practical application of scientific principles, making learning fun and memorable. Finally, constructing a rubber band car fosters creativity and problem-solving skills as builders experiment with different designs and materials to improve performance.

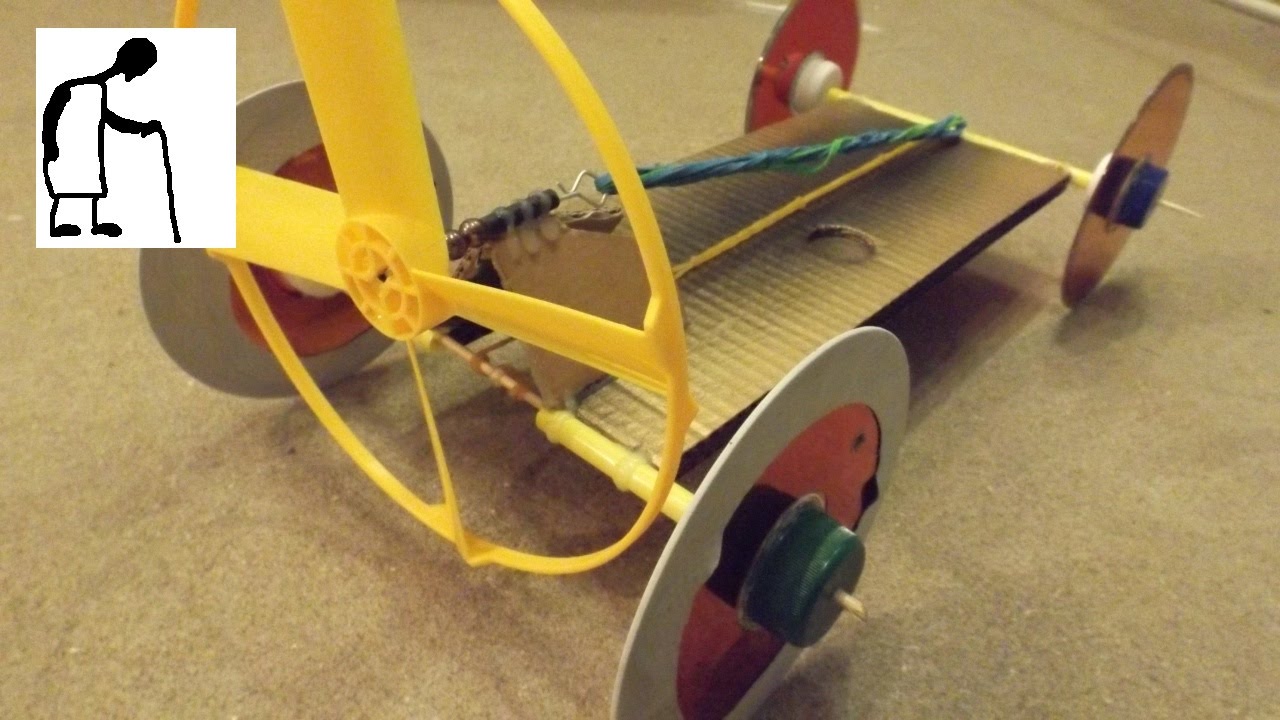

An action plan for your rubber band car project might involve the following steps: 1) Gather materials: cardboard, wooden skewers, rubber bands, bottle caps, glue. 2) Design the chassis: sketch the car's body and determine axle placement. 3) Construct the chassis: cut and assemble the cardboard body. 4) Attach the axles: insert skewers through the body, ensuring they rotate freely. 5) Attach the wheels: secure bottle caps to the skewers as wheels. 6) Create the propulsion system: add a hook or notch for the rubber band. 7) Test and refine: wind the rubber band and test the car's performance. Make adjustments as needed.

Advantages and Disadvantages of Rubber Band Powered Cars

| Advantages | Disadvantages |

|---|---|

| Educational and engaging | Limited range and speed |

| Affordable and uses readily available materials | Can be fragile depending on materials |

| Promotes creativity and problem-solving | Performance affected by environmental factors like temperature and surface |

FAQ: How do I make my car go faster? Ensure minimal friction, use a strong rubber band, and experiment with different wheel sizes. How do I make my car go straighter? Ensure proper wheel alignment and a balanced chassis. What type of rubber band is best? Thicker rubber bands generally store more energy.

In conclusion, building a DIY rubber band powered car is a rewarding experience that combines learning, creativity, and fun. From understanding basic physics principles to troubleshooting design challenges, this project offers a valuable educational opportunity. Whether you're a seasoned engineer or a curious beginner, the satisfaction of seeing your creation zoom across the floor is unparalleled. So, gather your materials, unleash your inner engineer, and embark on this exciting journey of building your own rubber band powered car. Explore different designs, experiment with various materials, and discover the endless possibilities of this simple yet powerful creation. The thrill of building something with your own hands and witnessing the principles of physics come to life is an experience that will stay with you long after the car has stopped rolling.

Rubber Band Powered Car Science Project - Trees By Bike

rubber band powered car - Trees By Bike

How To Create A Rubber Band Car - Trees By Bike

Rubber Band Car Designs For Distance - Trees By Bike

Dual Powered Rubber Band Powered Car - Trees By Bike

Diy Rubber Band Car - Trees By Bike

Make A Rubber Band Car - Trees By Bike

How to Make a Rubber Band Powered Car Project and Designs - Trees By Bike

How to make a Rubber Band powered Car with pencil - Trees By Bike

Cardboard Rubber Band Powered Car - Trees By Bike

How to make Rubber Band Powered CAR diy toy car - Trees By Bike

Rubber Band Powered Car 1 x size 64 - Trees By Bike

How to make a Rubber Band powered Car - Trees By Bike

Wheels Toy Car Project at Gregory Reed blog - Trees By Bike

How to make a Rubber Band powered Car DIY Rubber Band powered Car - Trees By Bike