Ever wondered how to transform simple household items into a miniature speed machine? Building a rubber band powered car is a fantastic way to explore the principles of physics and engineering while having a blast. This guide provides a comprehensive overview of designing, constructing, and optimizing your own rubber band powered car, from basic concepts to advanced techniques.

Constructing a rubber band powered vehicle isn't just a fun activity; it's a valuable learning experience. It's a hands-on way to grasp concepts like potential and kinetic energy, friction, and aerodynamics. By tweaking your design and experimenting with different materials, you can witness firsthand how these principles affect performance.

The history of rubber band powered toys can be traced back to the early 20th century, shortly after the invention of vulcanized rubber. These simple yet ingenious toys have entertained generations, sparking an interest in mechanics and engineering in countless young minds. The enduring appeal of creating a rubber band car lies in its accessibility and the satisfaction of seeing your creation come to life.

One of the main challenges in rubber band car construction is optimizing energy transfer. The goal is to convert the potential energy stored in the stretched rubber band into forward motion as efficiently as possible. Factors like friction, weight distribution, and the design of the axle and wheels all play a crucial role in determining how far and fast your car will travel.

Understanding the core mechanics is key to successful rubber band car design. The rubber band acts as the engine, storing potential energy when stretched. When released, this energy is converted into kinetic energy, causing the axle to rotate and propel the car forward. Simple designs might involve a single rubber band looped around an axle, while more complex designs utilize gear systems for increased speed or distance.

Building rubber band cars offers several benefits. Firstly, it's an excellent educational tool, providing practical experience with scientific principles. Secondly, it encourages problem-solving skills as builders troubleshoot design flaws and experiment with improvements. Finally, it's a fun and engaging activity that can be enjoyed by all ages.

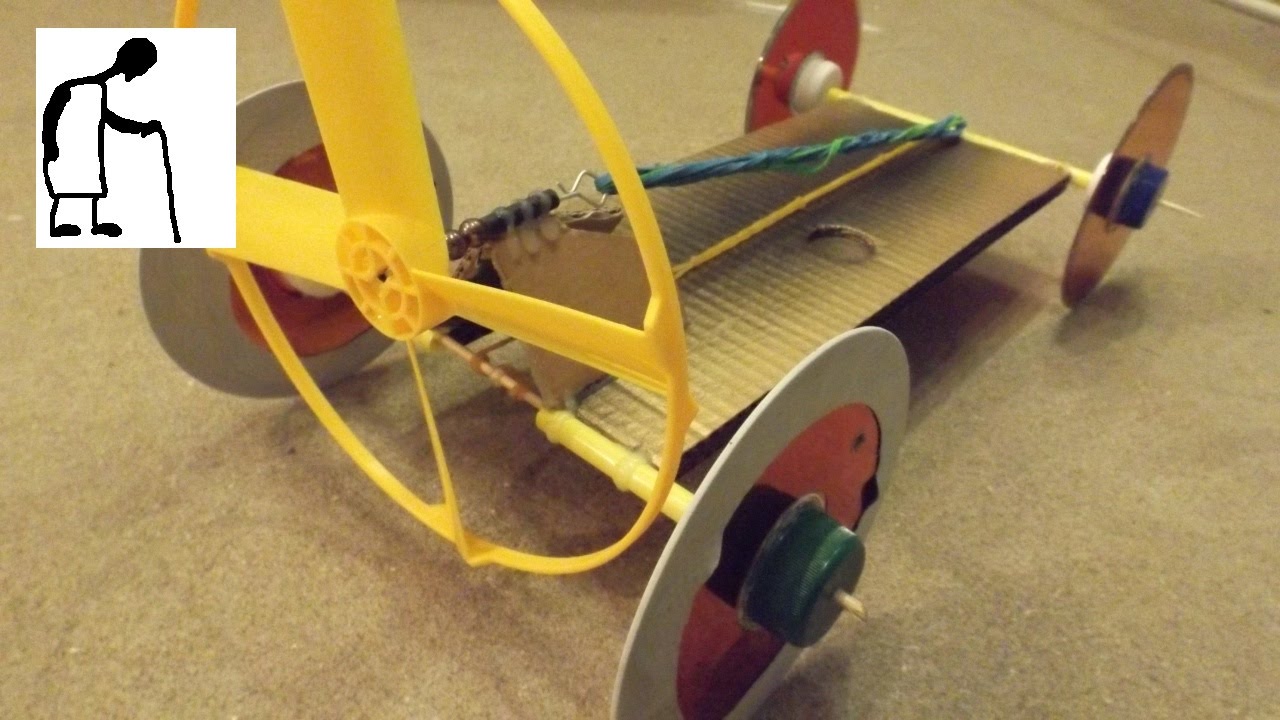

Let's create a simple rubber band powered car. You'll need a chassis (a sturdy base, like a piece of cardboard or wood), axles (wooden dowels or skewers work well), wheels (bottle caps or buttons can be used), and of course, rubber bands. Attach the axles to the chassis, ensuring they can rotate freely. Secure the wheels to the axles, then loop a rubber band around the rear axle. Wind the axle to stretch the rubber band, and release to see your creation zoom!

Advantages and Disadvantages of Building Rubber Band Powered Cars

| Advantages | Disadvantages |

|---|---|

| Educational and engaging | Can be time-consuming for complex designs |

| Promotes problem-solving skills | Limited range and speed compared to other powered vehicles |

| Affordable and accessible materials | Performance can be affected by environmental factors like temperature and humidity |

FAQ: What kind of rubber bands work best? Thicker rubber bands generally provide more power.

FAQ: How can I make my car go faster? Reducing friction and optimizing weight distribution are key.

FAQ: What materials can I use for the chassis? Cardboard, wood, or even plastic bottles can be used.

FAQ: How can I attach the wheels to the axles? Glue, tape, or even small nails can be used.

FAQ: What if my car veers to one side? Check for alignment issues with the axles and wheels.

FAQ: How can I make my car go further? Experiment with different rubber band sizes and winding techniques.

FAQ: Where can I find more resources on building rubber band cars? Online tutorials and educational websites offer a wealth of information.

FAQ: Can I add gears to my car? Yes, gears can increase speed or torque, but add complexity to the design.

One tip for boosting performance is to use lightweight materials for the chassis. Another trick is to lubricate the axles to reduce friction.

In conclusion, building a rubber band powered car is more than just a fun pastime; it's a rewarding experience that fosters creativity, problem-solving, and a deeper understanding of scientific principles. From simple designs to more complex creations incorporating gears and advanced aerodynamics, the possibilities are endless. By exploring the challenges and experimenting with different solutions, you can unlock the full potential of this classic toy and experience the thrill of seeing your own engineered vehicle come to life. So gather your materials, dive into the exciting world of rubber band powered cars, and unleash your inner engineer. Take the first step today and experience the satisfaction of building something with your own hands!

Rubber Band CAR by Hoang M Nguyen at Coroflotcom - Trees By Bike

Make a Rubber Band - Trees By Bike

Building A Rubber Band Powered Car - Trees By Bike

How to make a Rubber Band powered Car DIY Rubber Band powered Car - Trees By Bike

How To Make a Car - Trees By Bike

Lightweight Rubber Band Powered Car 6 Steps with Pictures - Trees By Bike

Rubber Band Powered Car Project - Trees By Bike

How to Make a Rubber Band Car - Trees By Bike

rubber band powered car - Trees By Bike

Simple DIY Rubber Band Car - Trees By Bike

Car Powered By Rubber Bands - Trees By Bike

88 Best images about A Kids - Trees By Bike

How To Make A Rubber Band Vehicle at Todd Batten blog - Trees By Bike

Designing a Simple 3D Printed Rubber Band Car Using Autodesk Fusion 360 - Trees By Bike

Build A Rubber Band Powered Car - Trees By Bike