Imagine trying to assemble a complex piece of furniture without instructions. Frustrating, right? Similarly, navigating the intricate world of hydraulic systems without a clear understanding of hydraulic schematic symbols is a recipe for confusion and potential disaster. These symbols are the universal language of hydraulics, providing a visual roadmap for engineers, technicians, and anyone working with these powerful systems.

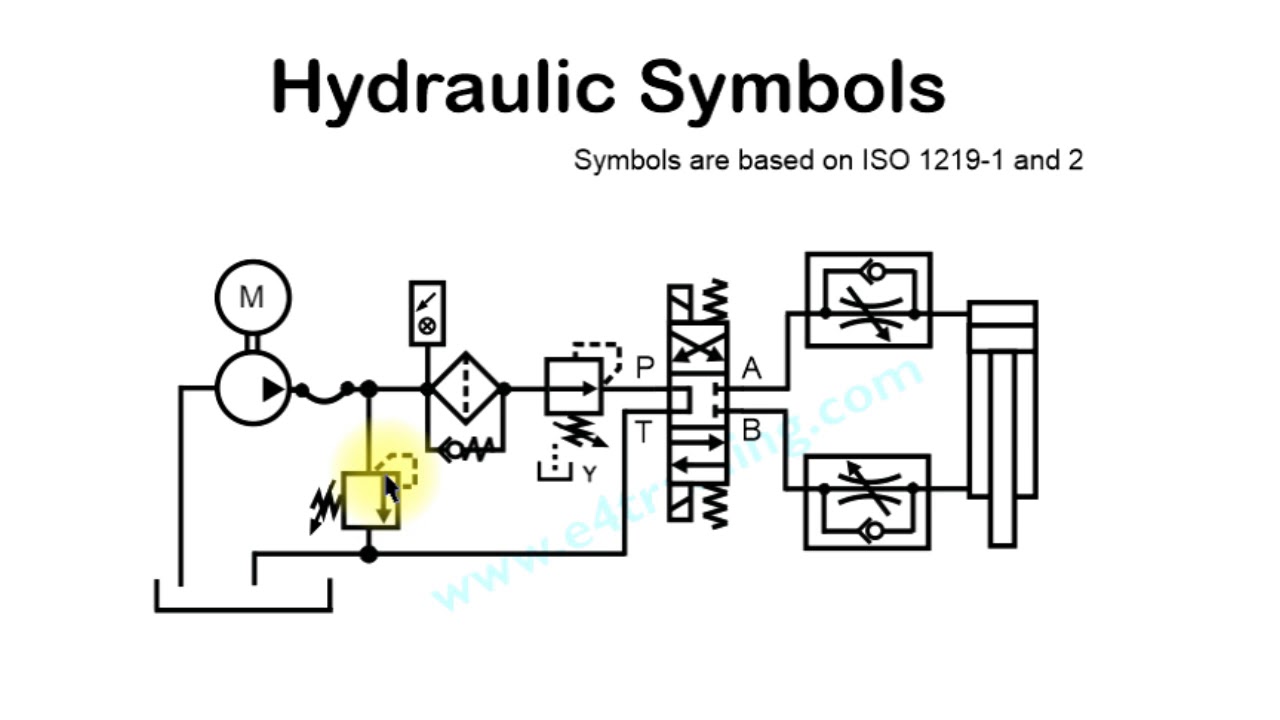

Hydraulic schematic symbols charts are essential tools for designing, analyzing, troubleshooting, and maintaining hydraulic systems. They represent various components, such as pumps, valves, actuators, and filters, allowing for a simplified representation of complex systems. Mastering these symbols unlocks the ability to effectively communicate design intent, diagnose malfunctions, and ensure smooth operation of hydraulic machinery across industries, from manufacturing and construction to aerospace and agriculture.

The history of hydraulic schematic symbols parallels the development of hydraulic technology itself. As hydraulic systems became more complex, the need for a standardized visual language grew. Over time, organizations like the International Organization for Standardization (ISO) played a key role in establishing universally recognized symbols, promoting clarity and collaboration across borders and disciplines. Early representations were often rudimentary sketches, evolving into the precise and standardized symbols we use today. The drive for improved communication and safety fueled the standardization efforts, minimizing ambiguity and potential misinterpretations.

One of the main issues related to hydraulic schematic symbols is the potential for misinterpretation if not properly understood. Variations in regional or company-specific standards can further complicate matters. This underscores the importance of adhering to established standards, such as ISO 1219-1, and ensuring proper training for anyone involved in interpreting or creating hydraulic diagrams. Consistent use of standardized symbols is paramount for avoiding errors in system design, maintenance, and troubleshooting.

A hydraulic schematic symbol represents a specific component within a hydraulic circuit. For example, a circle with an arrow pointing inwards represents a pump, while a square with an arrow traversing it signifies a directional control valve. Understanding these symbols is crucial for understanding the overall system function. A hydraulic schematic diagram, also known as a hydraulic circuit diagram, uses these symbols to illustrate the interconnectedness and flow of hydraulic fluid within a system. It serves as a blueprint for the system's operation.

One key benefit of using hydraulic schematic symbols is improved communication. They provide a clear and concise way to convey complex system designs to others, regardless of language barriers. This standardized language fosters effective collaboration among engineers, technicians, and operators. Secondly, using hydraulic symbols simplifies troubleshooting. By visually tracing the flow of fluid and the function of each component, technicians can quickly pinpoint potential problems, reducing downtime and improving efficiency. Thirdly, these symbols are essential for proper system documentation. Detailed schematic diagrams provide valuable information for maintenance, repairs, and future modifications, contributing to the longevity and reliability of the hydraulic system.

To successfully implement hydraulic schematic symbols, start by obtaining a comprehensive symbol chart conforming to recognized standards. Ensure that all team members involved in the design, operation, or maintenance of the system are familiar with these symbols. When creating or interpreting diagrams, maintain consistency in symbol usage and labeling. Regularly review and update diagrams to reflect any system modifications. Finally, always prioritize clarity and accuracy in your schematic representations.

Advantages and Disadvantages of Standardized Hydraulic Symbols

While the advantages of standardized hydraulic symbols are significant, some potential drawbacks exist:

| Advantages | Disadvantages |

|---|---|

| Clear and concise communication | Requires training and understanding |

| Simplified troubleshooting | Potential for misinterpretation if standards are not followed |

| Improved system documentation | Can be complex for very large systems |

Real-world examples of hydraulic schematic symbols in action include diagrams for aircraft landing gear systems, industrial robotic arms, construction equipment like excavators, and agricultural machinery such as tractors. These diagrams are critical for ensuring the safe and efficient operation of these complex hydraulic systems.

A common challenge is the lack of consistent training on hydraulic schematic symbols, which can lead to misinterpretations and errors. The solution lies in implementing comprehensive training programs for all personnel working with hydraulic systems. Another challenge is keeping diagrams up-to-date with system modifications. Implementing a robust revision control system can address this issue.

Frequently Asked Questions about hydraulic schematic symbols include: What is the symbol for a pressure relief valve? How do I represent a variable displacement pump? Where can I find a comprehensive hydraulic symbol chart? What are the ISO standards for hydraulic symbols? What is the difference between a pilot-operated valve and a direct-operated valve (represented symbolically)? How do I represent a hydraulic accumulator on a schematic? How do I interpret the flow direction on a hydraulic schematic? What are the common symbols for different types of cylinders?

A valuable tip for working with hydraulic schematic symbols is to use software tools designed specifically for creating and managing hydraulic diagrams. These tools often include libraries of standard symbols and features that simplify the process of creating and editing complex diagrams.

In conclusion, understanding and utilizing hydraulic schematic symbols is paramount for anyone working with hydraulic systems. These symbols provide a crucial link between design, operation, and maintenance, fostering clear communication, simplifying troubleshooting, and improving overall system efficiency. From designing new systems to maintaining existing ones, a firm grasp of these symbols empowers professionals to effectively navigate the complexities of hydraulic technology. By embracing standardized symbols and best practices, we contribute to safer, more efficient, and more reliable hydraulic systems across diverse industries. Investing in training and resources related to hydraulic schematic symbol interpretation is an investment in the future of your hydraulic systems and the success of your operations. Take the time to learn these symbols, and unlock the full potential of hydraulic power.

Hydraulic Schematic Symbols Explained - Trees By Bike

Hydraulic Schematic Diagram Symbols - Trees By Bike

Symbols For Hydraulic Schematics - Trees By Bike

How To Read Hydraulic Schematics Pdf - Trees By Bike

Booklet Pneumatic Valve Symbols Chart - Trees By Bike

Hydraulic Schematic Symbols Chart Pdf - Trees By Bike

Hydraulic Valve Symbols Schematics - Trees By Bike

Hydraulic Schematic Symbols Chart Pdf - Trees By Bike

Symbols For Hydraulic Schematics - Trees By Bike

Hydraulic Schematic Symbols Chart - Trees By Bike

hydraulic schematic symbols chart - Trees By Bike

Basic Hydraulics Symbols at James Cooper blog - Trees By Bike

Hydraulic Schematic Symbols Chart Pdf - Trees By Bike

Hydraulic Schematic Symbols Explained - Trees By Bike

Fluid Circuit Diagram Symbols - Trees By Bike