Imagine gliding across the shimmering expanse of the water, the sun kissing your skin, the wind whispering secrets in your ear. But what if this idyllic scene is abruptly interrupted by the dreaded sputter of an empty fuel tank? A nightmare scenario, indeed. This is why understanding the intricacies of your boat's fuel gauge, and more importantly, knowing how to install one correctly, is paramount to a blissful boating experience. It’s not merely about avoiding a mechanical hiccup; it’s about cultivating a deeper connection with your vessel and embracing the self-sufficiency that comes with nautical know-how.

Fuel gauges, seemingly humble instruments, hold the key to unlocking uninterrupted aquatic adventures. They are the silent guardians against unexpected interruptions, ensuring your journey remains smooth and anxiety-free. But how did these essential devices come to be? While the precise origin of marine fuel gauges is shrouded in the mists of maritime history, their evolution mirrors the broader development of engine technology. As boat engines became more sophisticated, so too did the need for accurate fuel measurement. Early gauges were simple mechanical affairs, relying on floats and levers. Today, electronic sensors and digital displays offer unprecedented precision.

The importance of proper fuel gauge installation cannot be overstated. An incorrectly installed gauge can lead to inaccurate readings, leaving you stranded miles from shore or worse, causing engine damage due to fuel starvation. The main issue surrounding fuel gauge installation is ensuring compatibility between the gauge, the sending unit in the fuel tank, and the boat’s electrical system. This often requires careful consideration of the tank shape and size, the type of fuel being used, and the voltage of the boat’s electrical system.

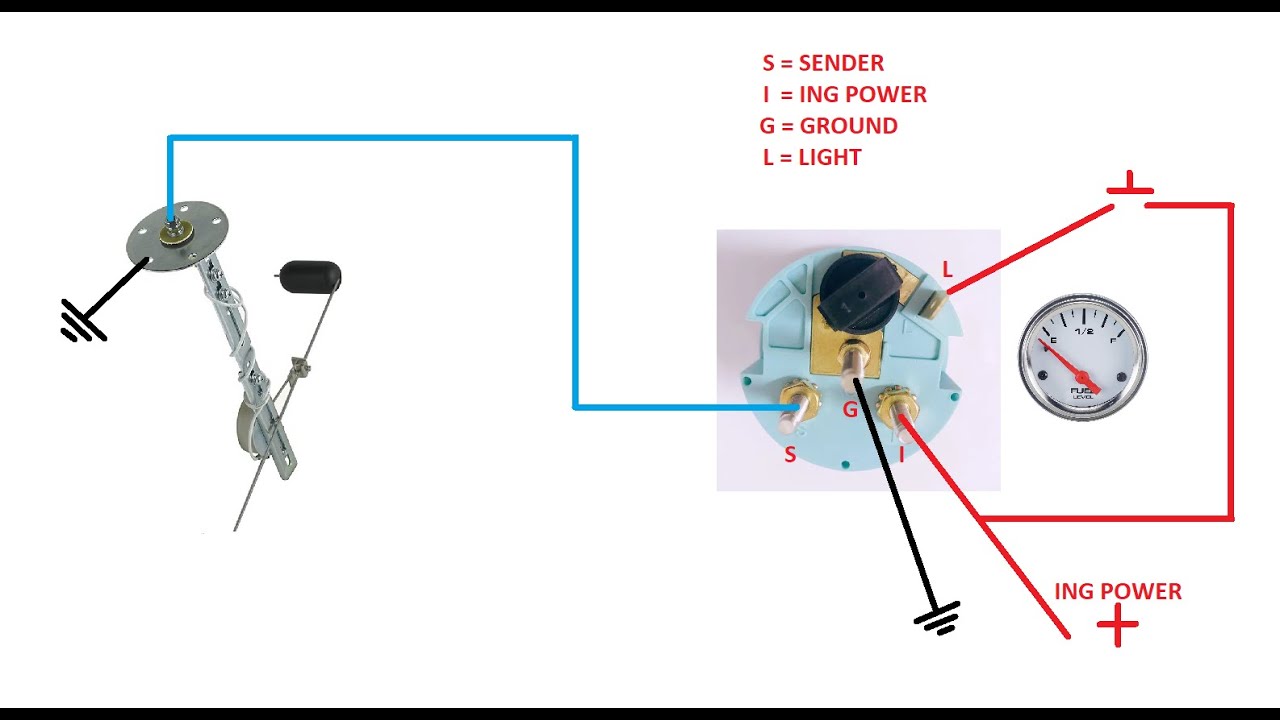

A fuel gauge system typically consists of three main components: the sending unit, the gauge itself, and the wiring that connects them. The sending unit sits inside the fuel tank and measures the fuel level. This information is then transmitted to the gauge, which displays the reading. Understanding the interplay between these components is crucial for successful installation.

For example, imagine a sailboat navigating through a remote archipelago. A correctly installed fuel gauge offers peace of mind, allowing the captain to confidently explore hidden coves and navigate challenging passages without the constant worry of running out of fuel. This translates to a more immersive and enjoyable sailing experience, fostering a deeper connection with the sea.

One benefit of a correctly installed fuel gauge is, of course, avoiding the inconvenience and potential danger of running out of fuel. Another advantage is the ability to accurately estimate fuel consumption, allowing for better trip planning and budgeting. Furthermore, a functioning fuel gauge can help identify potential fuel leaks or other issues within the fuel system.

An action plan for fuel gauge installation might involve first selecting the appropriate gauge and sending unit for your boat. Then, carefully plan the wiring route, ensuring it is protected from the elements and away from any potential hazards. Finally, meticulously follow the manufacturer’s instructions for installation and testing.

Advantages and Disadvantages of DIY Fuel Gauge Installation

| Advantages | Disadvantages |

|---|---|

| Cost savings | Potential for errors |

| Sense of accomplishment | Risk of damaging equipment |

| Increased understanding of your boat's systems | Time commitment |

Best practices for installation include ensuring a clean and dry working environment, using marine-grade wiring and connectors, and double-checking all connections before testing the system. After installation, calibrate the gauge to ensure accurate readings.

Frequently asked questions often revolve around compatibility issues, troubleshooting tips, and wiring diagrams. Consulting online forums, manufacturer websites, or experienced marine technicians can provide valuable insights.

Tips and tricks for a smooth installation might include using a fuel tank sealant to prevent leaks, using heat shrink tubing to protect wire connections, and testing the gauge with a known quantity of fuel to ensure accuracy.

In conclusion, mastering the art of fuel gauge installation empowers you to take control of your boating destiny. It’s more than just a practical skill; it’s a ritual of self-reliance, a testament to your commitment to the nautical life. By understanding the intricacies of your boat’s fuel system and following the steps outlined above, you can transform a potentially daunting task into a rewarding experience. Embracing this knowledge will not only enhance your safety and enjoyment on the water but also deepen your connection with your vessel, unlocking a world of aquatic adventures and fostering a sense of true nautical mastery. So, take the helm, embrace the challenge, and set sail towards a horizon of endless possibilities.

Marine Gauge Wiring Diagram For Gas - Trees By Bike

How To Install Fuel Gauge On Boat - Trees By Bike

Fuel Gauge Wiring Diagram Chevy - Trees By Bike

Wiring Fuel Gauge To Sending Unit - Trees By Bike

How To Install Fuel Gauge On Boat - Trees By Bike

How To Install Fuel Gauge On Boat - Trees By Bike

How To Install Fuel Gauge On Boat - Trees By Bike

Respectively light bulb mistress how to wire a boat fuel gauge Petrify - Trees By Bike

Fuel Pump On Boat Not Working at Pearl Gregory blog - Trees By Bike

Marine Fuel Sender Wiring Diagram - Trees By Bike

Lund Boat Fuel Sender Wiring - Trees By Bike

Wiring Diagram For Boat Fuel Gauge - Trees By Bike

How To Install Fuel Gauge On Boat - Trees By Bike

How To Wire Boat Gauges - Trees By Bike