Ever wondered about those numbers and letters stamped on your wheels? They’re not just random codes; they unlock a crucial piece of information: your wheel pattern. Understanding this seemingly small detail can make a world of difference when upgrading or replacing your wheels, ensuring a perfect fit and optimal performance. This guide will take you on a journey into the world of wheel pattern measurement, empowering you to choose the right wheels with confidence.

Identifying your wheel pattern, often referred to as the bolt pattern or PCD (Pitch Circle Diameter), is the foundation of proper wheel selection. It defines the arrangement of the lug holes – how many there are and how far apart they are spaced. An incorrect wheel pattern simply won’t fit, potentially leading to safety hazards and performance issues.

The history of wheel pattern measurement is closely tied to the evolution of automotive engineering. As cars became more sophisticated, the need for standardized wheel fitments became increasingly important. Accurately determining the bolt pattern is essential for ensuring compatibility between wheels and hubs, guaranteeing safety and performance across various vehicle makes and models. Over time, manufacturers developed a universal system for describing wheel patterns, enabling seamless communication and interchangeability.

The primary challenges associated with wheel pattern measurement involve accurate measurement and proper interpretation of the results. Without the right tools and knowledge, it's easy to misread measurements or misinterpret the markings on your existing wheels. However, armed with the correct techniques and information, deciphering your wheel pattern becomes a straightforward process.

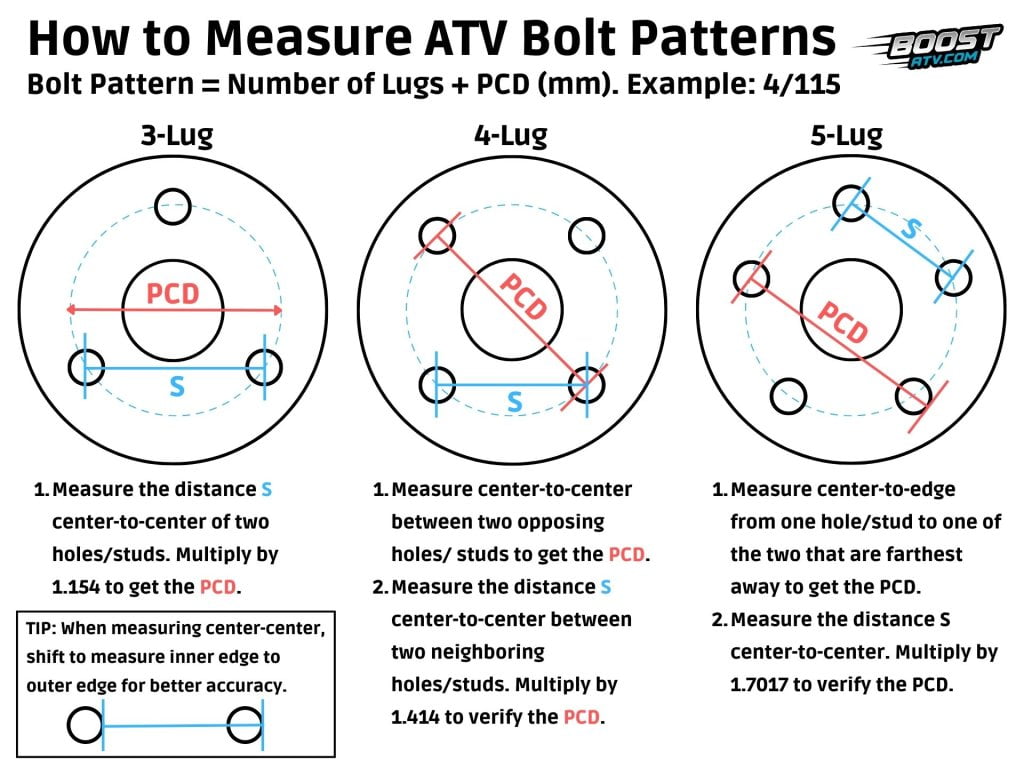

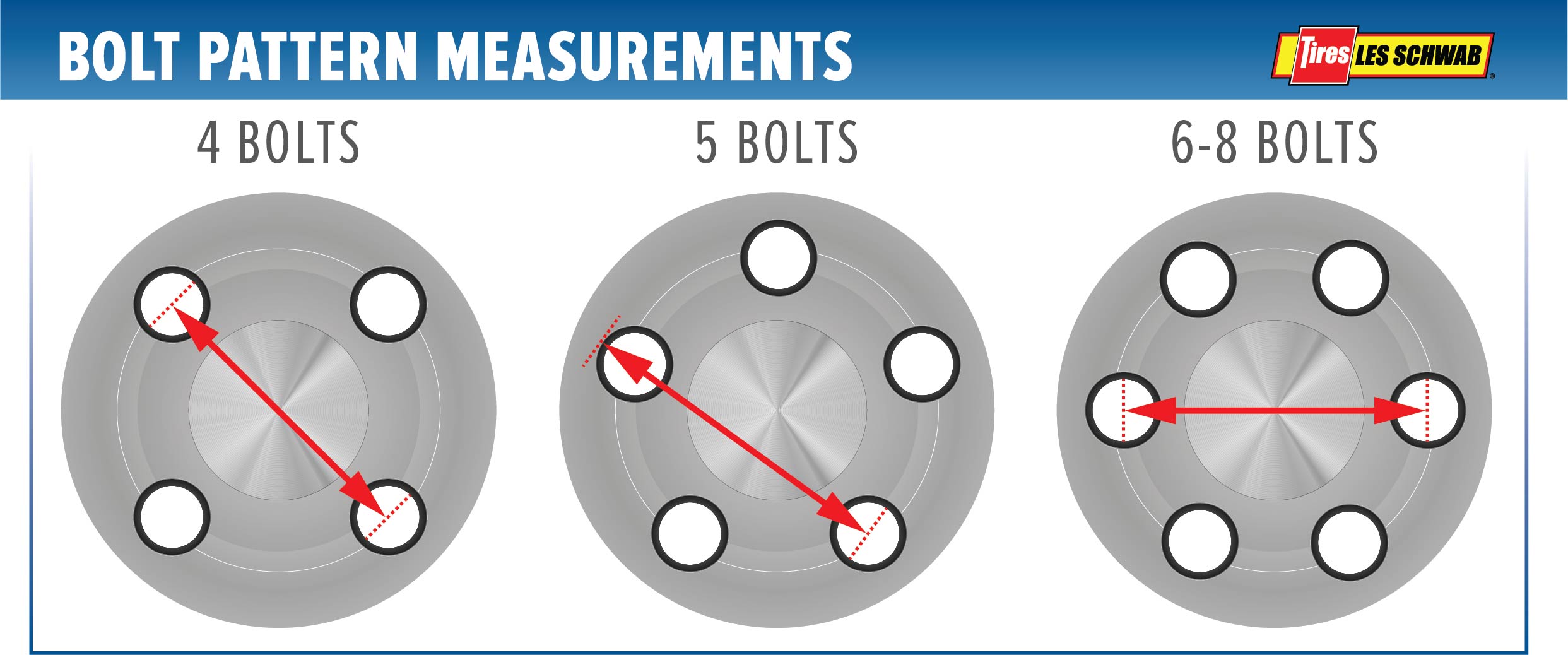

There are several methods for determining your wheel pattern. For wheels with an even number of lug holes, measure the center-to-center distance between two opposite lug holes. For wheels with an odd number of lug holes, measure from the center of a lug hole to the furthest point on the opposite side of the wheel hub and then use a formula to calculate the PCD. Understanding which measurement technique applies to your specific wheel is the key to accurate identification.

Knowing your wheel pattern offers several significant benefits. Firstly, it ensures you choose compatible wheels, preventing costly mistakes and ensuring a safe fit. Secondly, it opens up a wider range of wheel choices, allowing you to personalize your vehicle’s appearance and performance. Finally, understanding your wheel pattern empowers you to make informed decisions about wheel upgrades, ensuring optimal handling and performance.

To measure your wheel pattern, you'll need a ruler or tape measure. For even-numbered lug patterns, measure directly between two opposing lug holes. For odd-numbered patterns, measure from the center of one lug hole to the outermost edge of the wheel hub directly opposite. Use online resources or charts to convert your measurement into the standard PCD format.

Advantages and Disadvantages of Measuring Your Own Wheel Pattern

| Advantages | Disadvantages |

|---|---|

| Saves money on professional measurement | Potential for inaccurate measurement |

| Empowering and educational | Requires some basic tools and knowledge |

Best Practices: 1. Clean the wheel hub for accurate measurements. 2. Double-check your measurements. 3. Use the correct measurement method for even or odd lug patterns. 4. Consult online resources for PCD conversion. 5. If unsure, consult a professional.

FAQs: 1. What is PCD? (Pitch Circle Diameter, the diameter of the circle formed by the center of your wheel's lug holes). 2. Why is it important? (Ensures proper wheel fitment). 3. What tools do I need? (Ruler or tape measure). 4. What if I can't find my wheel pattern? (Consult a professional or online resources). 5. Can I change my wheel pattern? (Generally, no, without significant modifications). 6. What happens if I use the wrong wheel pattern? (Safety hazards and performance issues). 7. Are there different measurement techniques? (Yes, for even and odd numbered lug patterns). 8. Where can I find more information? (Online resources and automotive forums).

Tips and Tricks: Use a digital caliper for increased precision. Take multiple measurements to ensure accuracy. Consult online wheel pattern calculators for easy conversion.

In conclusion, understanding how to measure wheel pattern is a crucial skill for any car enthusiast. From ensuring safety and optimal performance to opening a world of customization possibilities, accurately determining your bolt pattern empowers you to make informed decisions about your vehicle’s wheels. While the process may seem daunting at first, armed with the knowledge and techniques outlined in this guide, you can confidently navigate the world of wheel fitments and select the perfect wheels to complement your ride. Don't underestimate the importance of this seemingly small detail – it's the key to unlocking your vehicle's full potential. Taking the time to learn proper wheel pattern measurement will not only save you potential headaches down the road but also enhance your overall driving experience. So, grab your measuring tools, put your newfound knowledge to the test, and confidently embark on your journey towards finding the perfect wheels. Remember, a correctly measured wheel pattern is the foundation of a safe, stylish, and high-performing ride.

2001 Chevy Silverado 1500 Bolt Pattern - Trees By Bike

Chevy 6 Lug Bolt Pattern - Trees By Bike

Chevy Rim Bolt Pattern - Trees By Bike

ATV Wheel Bolt Pattern and Lug Pattern Explained - Trees By Bike

Bmw Bolt Pattern Size - Trees By Bike

Chevy 5 Lug Truck Bolt Pattern - Trees By Bike

How Do You Measure Wheel Lug Pattern at Mattie Smith blog - Trees By Bike

2015 Dodge Ram Bolt Pattern - Trees By Bike