Thinking about adding a subpanel 100 feet from your main electrical panel? A detached workshop, a new garage, or maybe even a tiny house in the backyard – whatever your project, powering it correctly is essential. And one of the most crucial aspects is selecting the right wire size for your 100-amp subpanel.

Getting the wire size right isn’t just about making things work; it’s about safety. Undersized wire can overheat, creating a fire hazard. Oversized wire, while safer, can be unnecessarily expensive. So, navigating this balance is key to a successful and safe installation.

This guide aims to walk you through determining the appropriate cable size for a 100-amp subpanel 100 feet from your main panel. We’ll explore factors influencing wire size, safety considerations, and practical tips to ensure a smooth and code-compliant installation.

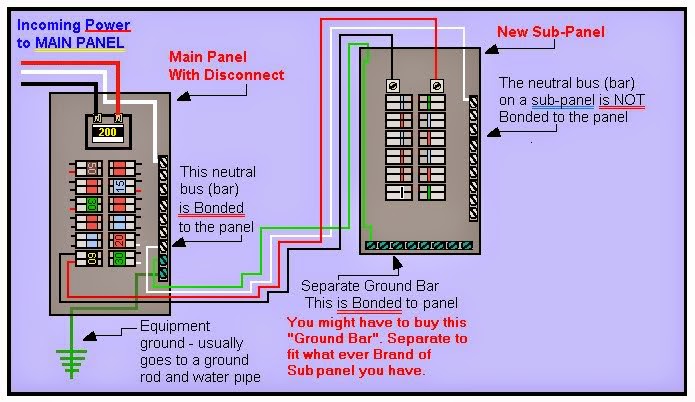

Wiring a subpanel can seem daunting, but with the right information, it’s a manageable project. Understanding the basics of wire sizing is empowering and can save you time, money, and potential headaches down the line. So, let's dive into the specifics of wiring your 100-amp subpanel located 100 feet away.

Choosing the correct wire gauge involves understanding a few key electrical principles. Distance, amperage, and voltage drop all play a role in determining the ideal wire size. A longer run, like the 100 feet in our scenario, requires a thicker wire to minimize voltage drop and ensure efficient power delivery.

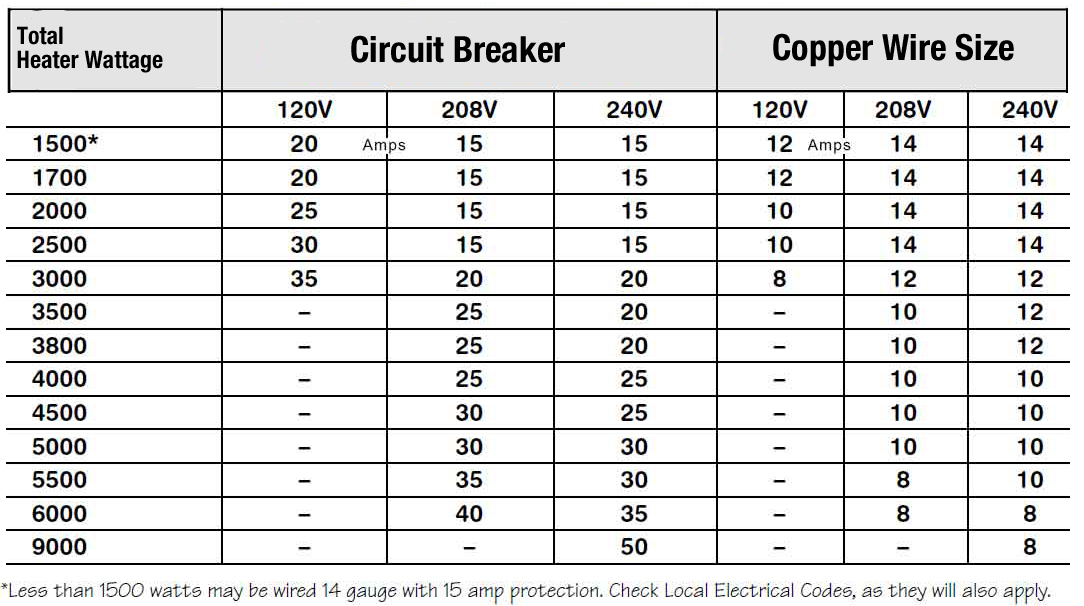

Historically, aluminum wiring was sometimes used for subpanels. However, due to concerns about connections and potential overheating, copper wiring has become the industry standard and is generally recommended for subpanel installations. The National Electrical Code (NEC) provides specific guidelines on appropriate wire sizes and materials for different applications, ensuring electrical safety and standardization across projects.

For a 100-amp subpanel at 100 feet, using #2 AWG copper wire with THWN-2 insulation is generally recommended to account for voltage drop. Consulting the NEC and local electrical codes is crucial to confirm compliance with specific requirements in your area. Always prioritize safety and consult with a qualified electrician if you are unsure about any aspect of the installation.

Benefits of Correct Wire Sizing:

1. Safety: Prevents overheating and potential fire hazards.

2. Efficiency: Ensures proper voltage delivery and minimizes power loss.

3. Code Compliance: Meets NEC requirements, ensuring a safe and legal installation.

Frequently Asked Questions:

1. What if my run is longer than 100 feet? You'll likely need a larger wire gauge to compensate for increased voltage drop.

2. Can I use aluminum wire? While possible, copper is generally recommended for its superior conductivity and ease of use.

3. Do I need a permit for this installation? Most jurisdictions require permits for subpanel installations. Check with your local authorities.

4. What is voltage drop? Voltage drop is the reduction in voltage that occurs as electricity travels through a wire.

5. Why is copper wire preferred? Copper offers better conductivity and is less susceptible to oxidation compared to aluminum.

6. How do I calculate voltage drop? You can use online calculators or consult the NEC for voltage drop calculations.

7. What is the NEC? The National Electrical Code (NEC) provides safety standards for electrical installations.

8. Should I hire an electrician? If you're not comfortable working with electricity, it's best to hire a qualified electrician.

Tips and Tricks:

Always double-check your calculations and measurements before purchasing wire.

Use high-quality wire connectors and ensure tight connections.

Understanding the importance of correct wire sizing for a 100-amp subpanel 100 feet away is crucial for a safe and efficient electrical system. By carefully considering the factors involved, consulting the NEC, and potentially seeking guidance from a qualified electrician, you can ensure that your subpanel installation adheres to safety standards and provides reliable power for your needs. Remember, prioritizing safety and code compliance is paramount in any electrical project. This investment in time and research will not only provide you with peace of mind but also contribute to the longevity and reliability of your electrical system. Take your time, plan carefully, and enjoy the satisfaction of a well-executed project.

100 amp service panel wire size - Trees By Bike

Wire Size For 150 Amp Sub Panel - Trees By Bike

wire size for 100 amp sub panel 100 feet away - Trees By Bike

What Wire Size For 100 Amp Sub Panel Thats 200 Feet Away Safety - Trees By Bike

Wire Size For 75 Amp Sub Panel - Trees By Bike

100 Amp Sub Panel Wiring - Trees By Bike

70 Amp Sub Panel Wiring - Trees By Bike

What Size Wire For 100 Amp Sub Panel Service - Trees By Bike

Wiring A 100 Amp Sub Panel From Main Panel - Trees By Bike

Wiring A 50 Amp Sub Panel - Trees By Bike

wire size for 100 amp sub panel 100 feet away - Trees By Bike

What Size Wire Do I Need for a 100 Amp Sub Panel - Trees By Bike

Wire Size For 150 Amp Sub Panel - Trees By Bike

50 Amp Sub Panel Wiring Diagram - Trees By Bike

100 Amp Sub Panel Wiring Size - Trees By Bike