Ever had that nagging feeling, that little voice in the back of your head whispering, “Are my wheels really on tight?” If you're a Jeep Wrangler owner, especially one who enjoys off-road adventures, understanding proper Jeep Wrangler lug nut torque is crucial. Ignoring this seemingly small detail could lead to anything from a wobbly wheel to a full-blown wheel detachment—a scenario no Jeeper wants to experience.

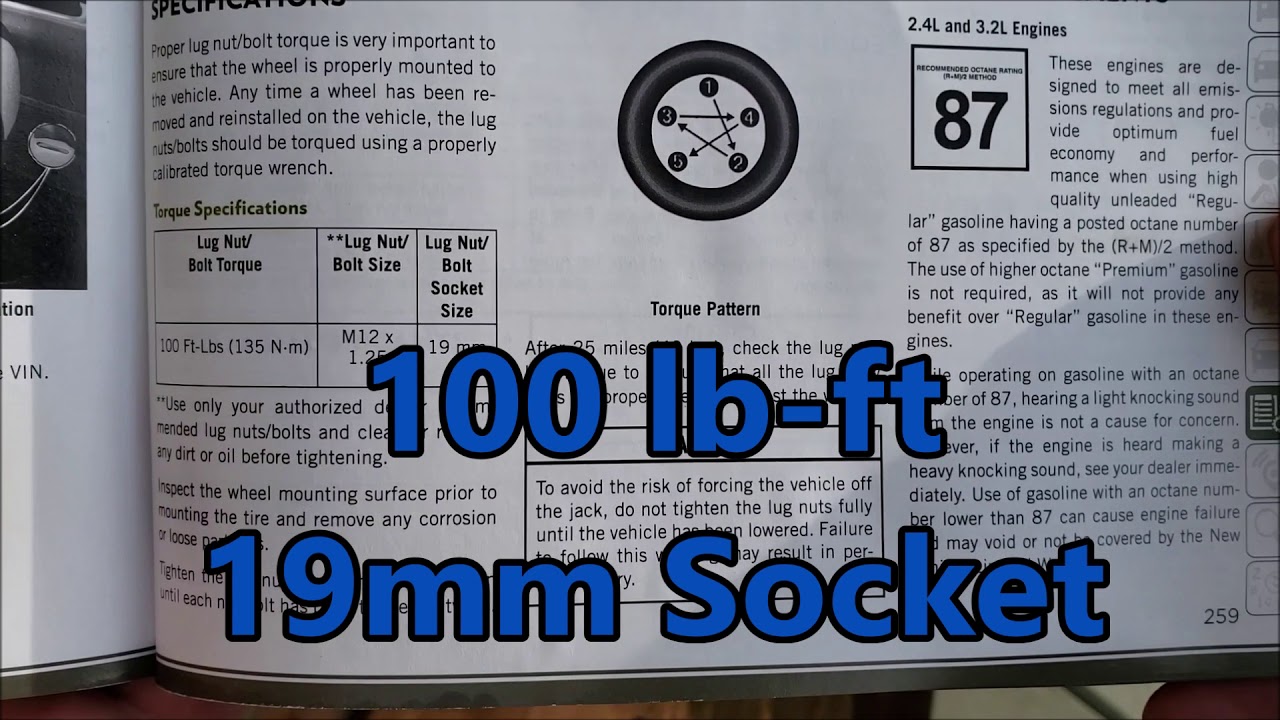

Proper wheel fastening relies on applying the correct Jeep lug nut torque. This isn't just about tightening the nuts as hard as you can. Over-tightening can damage the wheel studs, rotors, or even the wheels themselves. Under-tightening, of course, risks the wheel coming loose, which can be extremely dangerous. So, what's the magic number? The correct Jeep Wrangler lug nut torque specification is crucial for safe and secure wheel attachment.

The history of the lug nut itself is surprisingly rich, evolving from simple cotter pins to the robust threaded fasteners we use today. As vehicles became more complex and powerful, the importance of proper wheel fastening became increasingly critical. For a Jeep Wrangler, designed to tackle challenging terrains, the integrity of the wheel assembly is paramount. This is where knowing the precise Jeep wheel lug nut torque becomes essential, ensuring your off-road adventures remain thrilling, not terrifying.

Determining the correct Jeep Wrangler lug nut torque isn't as simple as picking a random number. The specific torque value depends on factors such as the year and model of your Wrangler, as well as the type of wheels you have. This information can usually be found in your owner's manual or on a sticker located inside the driver's side doorjamb. A quick online search using terms like “Jeep Wrangler JK lug nut torque” or "Jeep Wrangler JL lug nut torque specs" can also yield results, but always double-check with official sources.

Why is this seemingly mundane detail so crucial? Imagine cruising down the highway or navigating a rocky trail, only to have a wheel come loose. The consequences could be catastrophic. Proper Jeep Wrangler lug nut torque ensures a secure connection between the wheel and the vehicle, preventing accidents and keeping you and your passengers safe. Beyond safety, correct torque also protects your Jeep's components, preventing premature wear and tear on the wheel studs, rotors, and wheels.

Benefits of proper torque include safety, preventing damage, and extending the life of your components.

Action plan: Consult your owner's manual, use a calibrated torque wrench, and re-torque after 50 miles.

Checklist: Torque wrench, owner's manual, properly inflated tire.

Advantages and Disadvantages of Using a Torque Wrench

| Advantages | Disadvantages |

|---|---|

| Prevents over-tightening and under-tightening | Can be expensive |

| Ensures proper wheel attachment | Requires proper calibration and usage |

Best Practices: 1. Use a calibrated torque wrench. 2. Consult your owner's manual. 3. Re-torque after 50 miles. 4. Rotate tires regularly. 5. Inspect lug nuts regularly.

Real examples: Loose wheels causing accidents, damaged studs from over-tightening. Specific examples would need credible sources to cite.

Challenges and solutions: Difficulty finding the correct torque spec (solution: consult manual), forgetting to re-torque (solution: set a reminder).

FAQ: What is torque? How do I use a torque wrench? What if I don’t have a torque wrench?

Tips and tricks: Mark your wrench for your Jeep's spec. Keep your wrench calibrated.

Proper Jeep Wrangler lug nut torque is more than just a minor detail; it's a critical aspect of vehicle safety and maintenance. Understanding the importance of correct torque, knowing where to find the specific specifications for your Jeep, and using a calibrated torque wrench are essential steps every Wrangler owner should take. By following these guidelines, you can ensure the safety of yourself, your passengers, and other drivers on the road, while also protecting your Jeep from potential damage. Don't let a loose wheel ruin your next adventure. Take the time to learn about and apply the correct Jeep Wrangler lug nut torque, and enjoy peace of mind on and off the road. Investing in a quality torque wrench and dedicating a few extra minutes to proper wheel installation can save you from significant headaches, costly repairs, and potentially dangerous situations down the line. Stay safe, Jeep on!

Jeep Grand Cherokee Lug Nut Torque Spec - Trees By Bike

2015 Jeep Patriot Lug Nut Torque - Trees By Bike

Jeep Grand Cherokee Lug Nut Torque Spec - Trees By Bike

Lug Nut Torque Jeep Grand Cherokee - Trees By Bike

Jeep Wrangler Wheel Lug Nut Torque - Trees By Bike

Jeep Wrangler Wheel Lug Nut Torque - Trees By Bike

2020 Jeep Grand Cherokee Lug Pattern - Trees By Bike

2011 Jeep Wrangler Jk Lug Nut Torque Spec - Trees By Bike

Jeep Tj Lug Nut Torque - Trees By Bike

Jeep Grand Cherokee Wheel Lug Torque Spec - Trees By Bike

Lug Nut Torque Jeep Grand Cherokee - Trees By Bike

Jeep Cherokee Lug Nut Torque Spec - Trees By Bike

Jeep Wrangler Jl Lug Nut Torque Specs - Trees By Bike

Ford Axle Nut Torque Specs - Trees By Bike

2021 Jeep Grand Cherokee Lug Nut Torque - Trees By Bike