Ever wondered what keeps your boat's engine from overheating and turning into a molten mess out on the water? It's not magic, it's a small, but mighty component: the boat motor water pump impeller. This unassuming rubber gadget is the heart of your outboard's cooling system, and neglecting it can lead to catastrophic engine failure. So, buckle up, because we're about to embark on a deep dive into the world of marine engine cooling and the vital role played by the water pump impeller.

The boat motor water pump impeller is essentially a flexible rubber vane wheel housed within the engine's water pump. Its primary function is to draw cooling water from the surrounding lake, river, or ocean and circulate it through the engine block, preventing overheating. Think of it like a tiny, constantly spinning fan that pushes water through your engine's veins.

While the exact origins of the impeller might be shrouded in the mists of internal combustion engine history, its importance is undeniable. Before impellers, raw water cooling systems were more rudimentary and less efficient. The advent of the impeller revolutionized marine engine cooling, making boats more reliable and powerful.

A malfunctioning or damaged boat water pump impeller can spell disaster. Overheating can warp engine components, seize pistons, and ultimately lead to expensive repairs or even a complete engine replacement. Common signs of a failing impeller include overheating, reduced water flow from the tell-tale, steam, and a burning rubber smell.

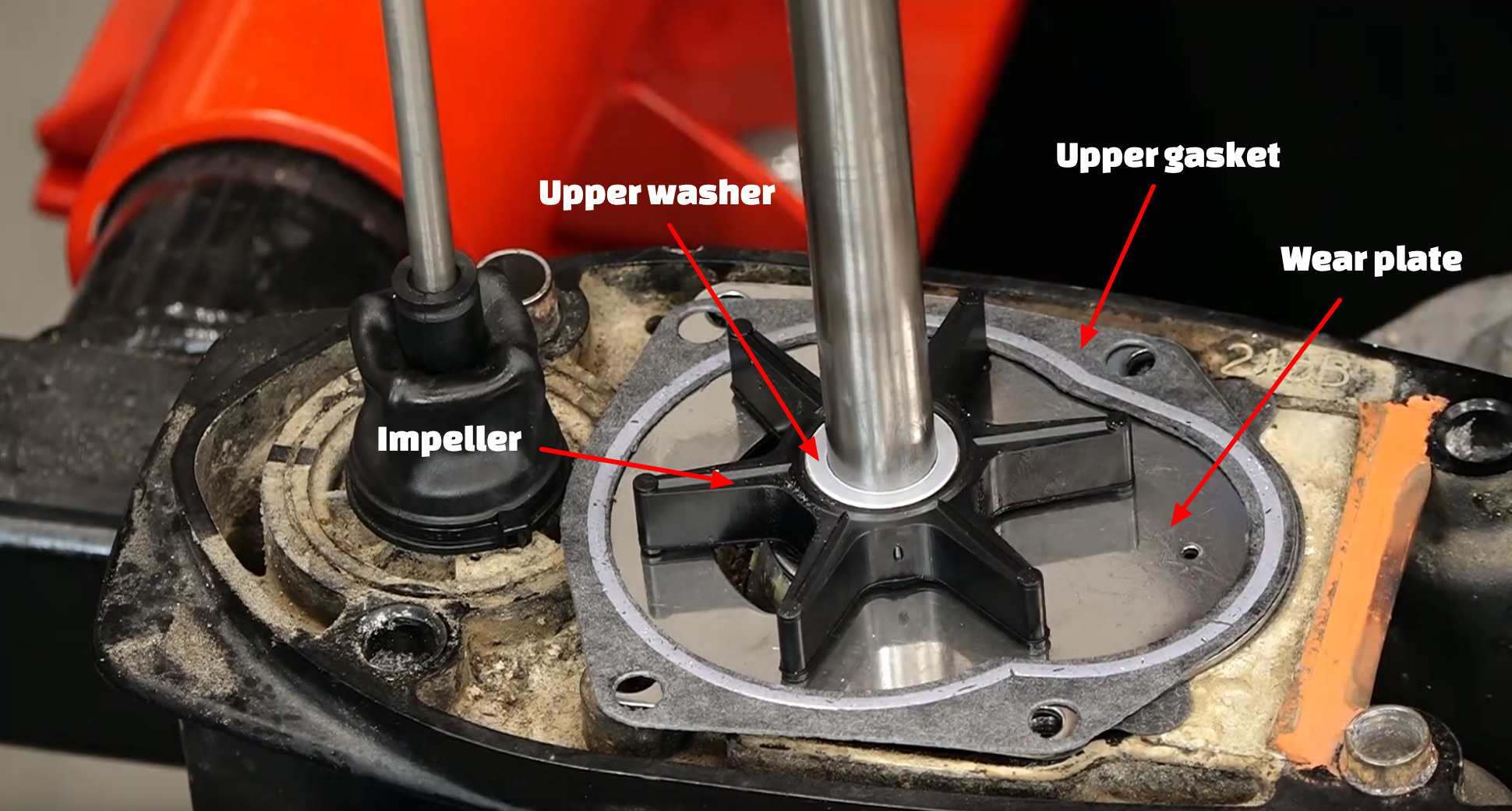

The impeller itself is surprisingly simple. It's typically made of a flexible rubber or neoprene compound designed to withstand constant rotation and the corrosive effects of saltwater. The vanes, often curved and precisely angled, create suction, drawing water into the pump and then forcing it out into the engine's cooling passages.

Impellers offer several crucial benefits. First and foremost, they ensure efficient engine cooling, preventing overheating and extending the life of your outboard. Secondly, their relatively low cost and ease of replacement make them a cost-effective maintenance item. Finally, a properly functioning impeller contributes to optimal engine performance, ensuring you get the most out of your time on the water.

Regular inspection and replacement of your boat’s water pump impeller is essential. Most manufacturers recommend changing the impeller annually or every 200 hours of use. A visual inspection can reveal cracks, tears, or missing vanes, indicating the need for replacement.

Here's a simple checklist for maintaining your outboard motor water pump impeller:

1. Inspect the impeller annually or every 200 hours.

2. Replace the impeller if any damage is found.

3. Keep spare impellers onboard.

4. Use a lubricant like glycerin during installation.Advantages and Disadvantages of Different Impeller Materials

While most impellers are made of rubber or neoprene, some specialized impellers use different materials. Here's a comparison:

| Material | Advantages | Disadvantages |

|---|---|---|

| Neoprene | Cost-effective, good flexibility, resists most chemicals | Can degrade over time, especially with ethanol fuels |

| Nitrile | Excellent resistance to chemicals and fuels, longer lifespan | Slightly more expensive than neoprene |

Five best practices for impeller maintenance include: 1) Regular inspection, 2) Using the correct impeller for your engine, 3) Proper installation using lubricant, 4) Flushing the cooling system after use in saltwater, and 5) Storing spare impellers in a cool, dry place.

Five real-world examples of impeller failures include overheating during a fishing trip, loss of power due to a shredded impeller, a burning rubber smell indicating impeller damage, a clogged cooling system caused by a deteriorated impeller, and engine seizure due to prolonged overheating from a failed impeller.

Five challenges related to impellers and their solutions: 1) Difficulty removing the impeller housing - use the proper tools and techniques. 2) Damaged impeller housing - replace the housing. 3) Impeller not seating correctly - ensure proper alignment. 4) Leaking water pump - replace seals and gaskets. 5) Overheating despite a new impeller - check for other cooling system issues.

FAQs:

1. How often should I replace my impeller? Annually or every 200 hours.

2. What are the signs of a bad impeller? Overheating, reduced water flow, steam, burning rubber smell.

3. Can I install the impeller myself? Yes, with the proper tools and instructions.

4. What type of impeller do I need for my engine? Consult your engine's owner's manual.

5. Why is my engine overheating even with a new impeller? Check for other cooling system issues.

6. Where can I buy a new impeller? Marine supply stores, online retailers.

7. How do I know if my water pump is working? Check the tell-tale stream.

8. What is the average cost of a boat motor water pump impeller? They typically range from $20-$50.

Tips and Tricks: Use a lubricant like glycerin during installation. Keep spare impellers onboard. Flush the cooling system after saltwater use.

In conclusion, the boat motor water pump impeller is a small but critical component that ensures the health and longevity of your outboard engine. Regular inspection, timely replacement, and proper maintenance are essential to avoid costly repairs and ensure enjoyable boating experiences. Understanding the function, importance, and potential problems associated with the impeller empowers boat owners to take proactive steps to protect their investment and enjoy countless hours on the water. Don't let a tiny piece of rubber ruin your boating adventures. Take care of your impeller, and it will take care of your engine. By following the advice and tips outlined in this article, you can help prevent impeller failure and keep your boat’s engine running smoothly for years to come. Remember to prioritize preventative maintenance and always be prepared for the unexpected while on the water. Happy boating!

Inboard Engine Cooling Systems - Trees By Bike

250 Hp Mercury Outboard 4 Stroke Engine Sale - Trees By Bike

Essential Outboard Maintenance Impeller Replacement - Trees By Bike

Gamefisher 5 Hp Outboard Parts - Trees By Bike

How Do Impeller Pumps Work at Michael Walden blog - Trees By Bike

Boat Motor Water Pump Impeller 0114812 Cooling System Pump Impeller - Trees By Bike

wolftale Boat Motor Water Pump Impeller Outboard Water Pump Impeller - Trees By Bike

Boat Motor Water Pump Impeller Water Pump Impeller 6L5 44352 00 - Trees By Bike

Replace Water Pump Impeller Johnson 90 Hp - Trees By Bike

boat motor water pump impeller - Trees By Bike

Mercury 40 Hp 2 Stroke Service Manual - Trees By Bike

New Water Pump Impeller For Johnson Evinrude 1015182025HP Outboard - Trees By Bike

Buy Boat Motor Water Pump Impeller Kit 17400 - Trees By Bike

HOW TO Replace Impeller Water Pump Mercury Outboard 75 hp - Trees By Bike

How Much Does It Cost To Replace A Water Pump On An Outboard Motor at - Trees By Bike